Hi All,

Wonder if someone can cast there eye over my graph feeds and see if this is correct?

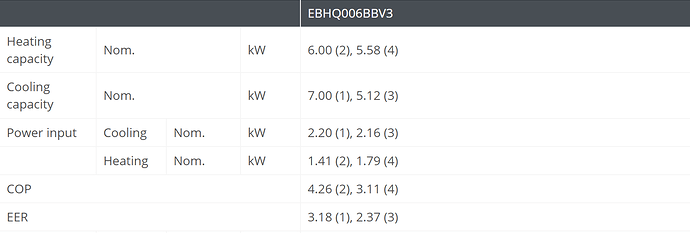

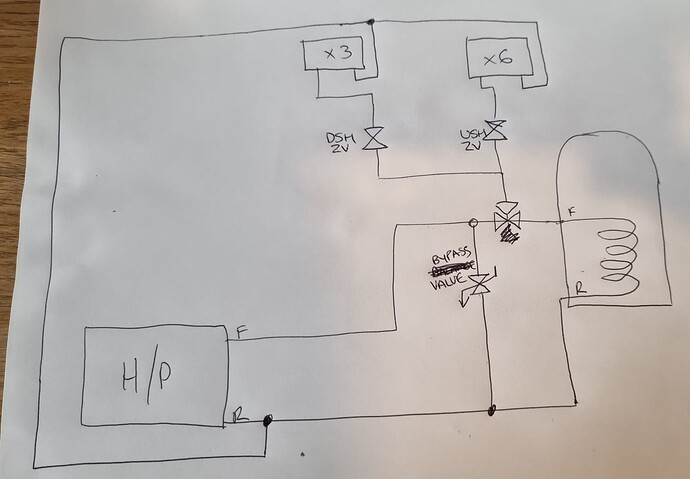

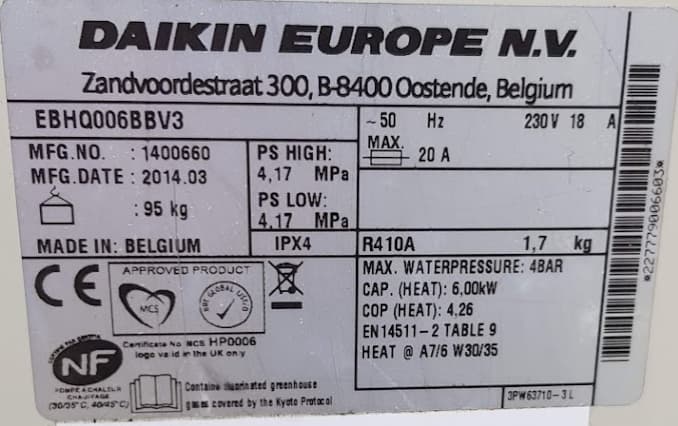

I have a 6KW Daikin Monoblock ASHP connected to a low temperature raditor systema and a 200l hot water tank. These are the details on the side of my outdoor unit.

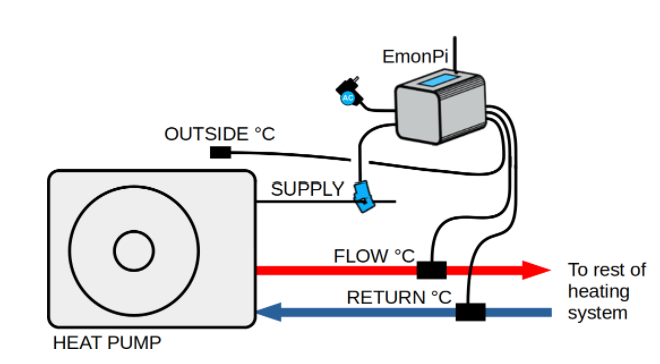

Recently ive clagged in 3 sensors. 1 under the bottom of the heat pump for the ambient and the flow and return temperatures. (I lagged the sensors after photo was taken  )

)

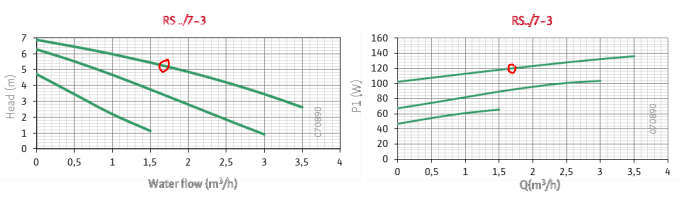

As i do not have a heat meter I am going be the level 2 system guide on the open energy monitor. See below for reference.

Because I want the data in HA aswell I have done all the calculations in HA and MQTT them across to emoncms. I followed the guide below for the relevent caluations.

https://learn.openenergymonitor.org/sustainable-energy/building-energy-model/heatpumpmodel

So Ill copy my HA sensor.yaml code incase anyone else is interested or sees an issue with it.

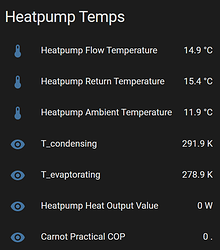

“T_condensing”

"{{ (states(‘sensor.heatpump_flow_temperature’) | float) | round(1) + 277 }}

“T_evaptorating”

“{{ (states(‘sensor.heatpump_ambient_temperature’) | float) | round(1) + 267 }}”

“Carnot Practical COP”

{{ 0.5 * ((float(states(‘sensor.t_condensing’))) / ((float(states(‘sensor.t_condensing’))) - (float(states(‘sensor.t_refrigerant’))))) | float | round(1) }}

“Heatpump Heat Output Value”

{{ (float(states(‘sensor.emon_heatpump_power’))) * (float(states(‘sensor.carnot_practical_cop’))) | round }}

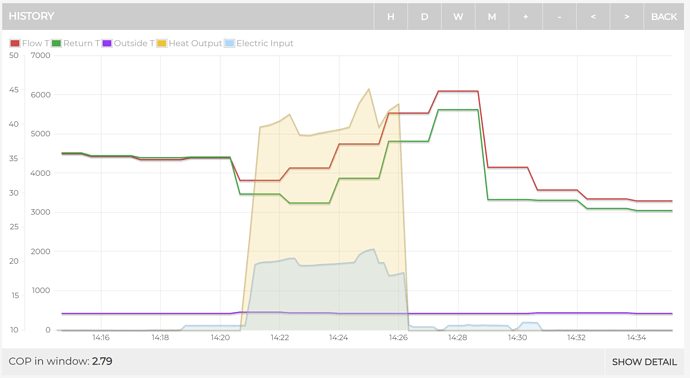

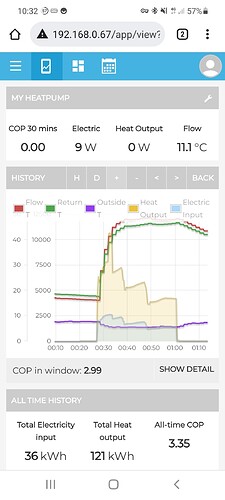

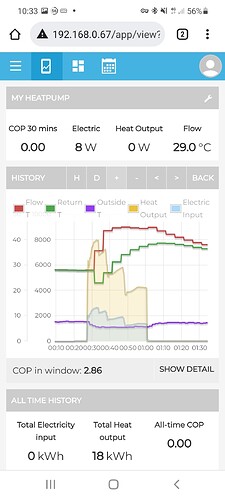

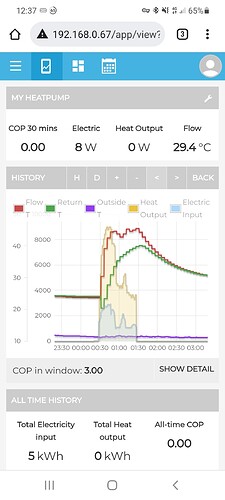

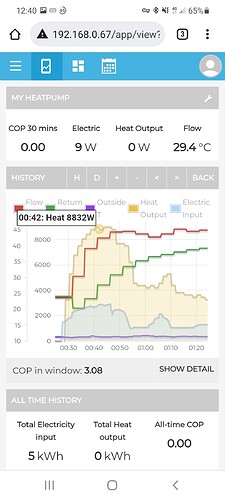

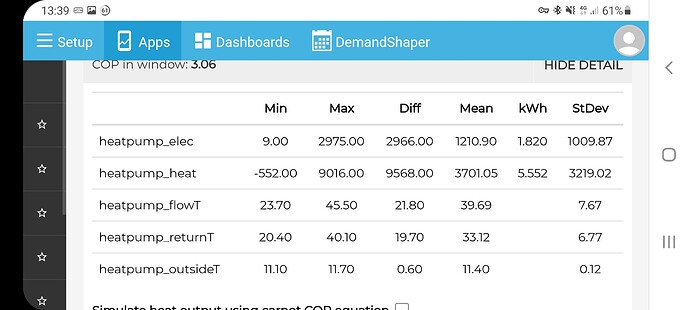

Ive set the My Heatpump App up and im now logging data.

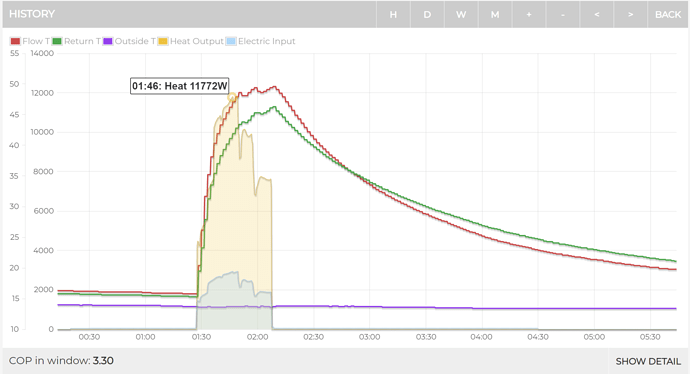

Last night the heatpump ran to heat the hot water. Do these figures look correct? The heat output was indicating nearly 12KW? The electrical input was nearly 3KW.

Going back to the info on the side of the outdoor unit it states 6kw @ 4.26COP and calulation of the website.

Heatpump_output= Power_input * Practical_COP

6000= Power_input * 4.26

Rearranging the formula we get

Power_ input = 6000 / 4.26 = 1408 watts (not sure what temp that is at???)

With that being calculated is 12KW and 3KW about right? Or have is just answered my own question.

Maybe this a question for heatpump guru @TrystanLea?

Any help comments would be much aprreciated .

Cheers

Gareth