Sorry but I can’t help it.

You are forgiven.

As an aside my mum was always tickled by the term “Where’s my bleeding key” when looking for the radiator bleed key. ![]()

Hi John

Ultimately, you wanna see if this is sorted by being able to run 100% DHW pump speed.

I found that running 50% pump speed was just a sticking plaster that masked the problem.

Plus, you should get better DHW performance running that pump with more flow rate.

Good point Mick sound advice.

I was in the loft today waiting for the DHW program to clicked in. As it started up I could clearly hear water gurgling through the 3 port valve, so I’m assuming there’s still more air in the system.

I will change the pump speed to 100% for the next runs. I’ve tried not to change too many things at once as it’s difficult to then track down what change made the difference in a positive or negative way.

Getting all the air out of the system is useful in other ways e.g. reduced corrosion, increased pump life span, increased efficiency and reduced noise, so it’s worthwhile to try and figure out what’s causing the air to be trapped and how it can be released.

@Zarch had a particularly tough time since he was using a plate heat exchanger on his Mixergy tank, apparently getting all the air out of a plate is tricky.

The easiest way to get all the air out of a plate is to mount it horizontally (all outlets pointing up).

I don’t think that’s the best way to operate it; certainly with refrigerants undergoing phase change etc; but it shouldn’t be too bad in that orientation with water and water and at high flowrates only.

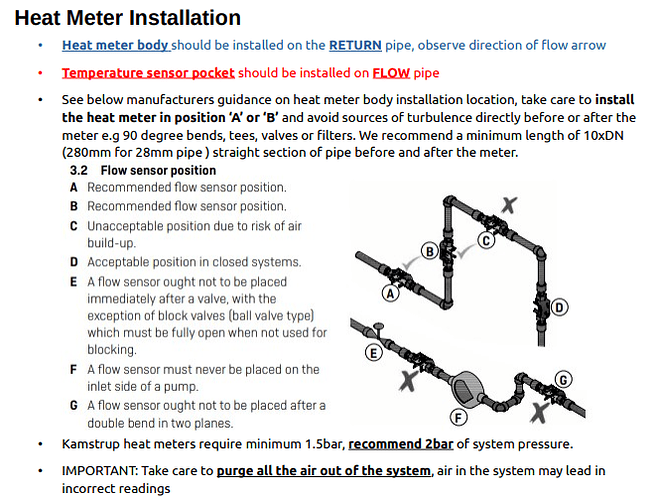

We’ve started recommending that all heat meters are on the flow side in these heat pump monitoring applications. You have greater static pressure in the flow sensing element this way; which delays the point where dissolved air decides to dissolve out.

(dissolved air being MUCH harder to kick out than basic trapped / entrained air)

[edited as I said heat out of a plate not air out of a plate - thanks Gwil for the spot]

My installer was around to commission last week and I got them to move the meter onto a clearer run of pipe away from the magnetic filter and bypass valve.

Doing this introduced lots of air into the system that I have been bleeding out and the heating was on yesterday allowing air to get into radiators where I blead it off.

However the situation doesn’t look to have improved:

Will just have to give it time and see what happens.

I can’t hear much air movement apart from a slight ‘tinkly’ sound that I could hear towards the end of a cycle. Makes me wonder if this is the dissolved air mentioned by others forming bubbles when at higher temperatures.

Surely there must be some way of getting this out, presumably it is getting redissolved when the water cools down.

Also surely there must be a reason that only a small number of us are experiencing this or is it just that lots of people haven’t noticed or cared too much because they have mainly been looking at heating cycles rather than DHW?

Could it help to raise my DHW target temperature to something like 55 degrees (currently 48) for a couple of runs to get more of the dissolved air to be released and have a chance to escape?

Get it all hot (on space heating), purge the air from rads, flip back and forth between heating / hot water to shift air into rads, purge the air from rads.

Bump up the static fill pressure. Then meters with flow sensor on the supply (rather than return) will experience higher static pressure and be less prone to air dissolving out etc.

Why don’t most experience this? Most don’t notice. Many use Sontex meters that are more robust to air but appear more vulnerable to muck.

Having AAVs (automatic air vents) installed at the highest points of your system is a big help to get rid of air, but you’ll probably still need to manually bleed rads for a few weeks to get all of it out. Could you post some photos of your system showing the location of the meter and the AAVS?

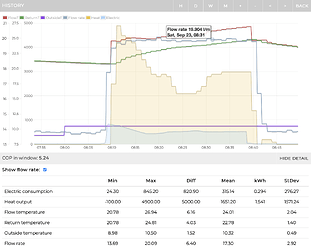

Update: on my erratic flow rate readings on the Kamstrup 403 post solution implementation

Mark from JMR Heating came on 20th Sept and fitted 2 additional AAVs on the flow and return pipes.

I have been running the heating and hot water circuits and bleeding air from the radiators every few days. I bled some more out today - I’m a bleeding expert now! ![]()

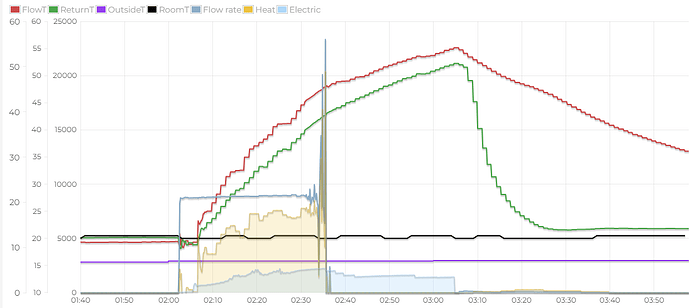

Flow rate reporting is now becoming a lot more stable during heating runs. This is from the 23rd Sept.

DHW runs had always been the more erratic for reporting flow rates with the Kamstrup. It’s so much sbetter than it was, but as you can see there are still some fluctuations in the readings.

However, it’s a marked improvement and points to the fact that there is most likely still more air in the system.

Sorry for the slow response.

I’ve made a video of me pointing at things as I couldn’t really work out a way to show it all with photos (sorry for my boring voice and the mess of wires I haven’ sorted out yet).

I have wondered if sometimes air trapped in the coil floats its way up after the DHW heating cycle and gets trapped below the 3 port valve. Just that sometimes when I have manually changed the valve between heating and the tank I have heard air moving.

Maybe I need a the valve to be rotated 90 degrees with a bit of horizontal with a automatic bleed valve.

My hot water runs don’t seem to be getting better with time.

I did try upping the pressure from 2 bar to roughly 2 1/3bar a while back which seem to help the run that was currently happening and maybe the one after that but then went back to the flow rate reading dropping out.

Thanks for the video, that explains things nicely. The AAV should be at the highest part of the system, since they’re in the cellar they won’t be doing much for central heating since all the air will rise up into your rads which you can bleed off. However, the AAV on the flow is the most important one for DHW. The location of it looks fine, can you check that it’s open? The little knob on top should be loose.

It’s not ideal that the heat meter is fitted between two out of plane bends:

i.e location G

Yes both AAVs are open. I have heard air coming out of one when I was trying to get air out of the system after the last work was done to it.

Not really sure where else I can put the meter. I thought it was ok after the double bend in two planes if it had a straight of 280mm or more. I think it does but haven’t measured exactly.

Maybe I could try getting it moved to one of the straighter bits of pipe between the ASHP and pipework in the video.

Maybe as @marko suggests I could try it on the flow instead, maybe on the bit between the AAV and 3 port valve.

Mmm tricky, I think a better location would be on the vertical return pipe. But there’s a good chance your issue is trapped air. Can you hear any air in the system during a DHW cycle? Air in the system will make the pump sound noisier. Is there any scope for putting an AAV at the height points above the cellar?

The pump doesn’t sound noisier but at the start of a DHW cycle I have heard air getting shifted and tinkling noise of what sounds like small bubbles occasionally well into the DHW cycle (which might confirm the dissolved air forming bubbles theory). There is the occasional glug on a space heating run but I think this isn’t as often now and this air is getting trapped in rads for bleeding.

Is there anything that can be done to reduce the ability of the water to hold dissolved air?

Something else I’ve noticed is that I think the AAVs are only really useful when the water is stationary or moving slowly as otherwise it is rushing past the tee. The only time I have heard air come out of one was on the lowest pump speed.

I think it would be a bit tricky to get an AAV on the higher section to the ASHP as the pipe is at ceiling level. It would have to be on the outside pipework which I’m guessing isn’t a great idea.

Getting dissolved air out of a system takes time, it’s harder with a low temperature system since it’s not possible to use high flow temperature to speed up the process. I reckon if you keep bleeding the system the air will subside overtime.

Air separators e.g Spirotech don’t work in low temperature heating systems.

That’s good to know.

Next possibly terrible idea… could I maybe use my immersion to get the tank up to a high temp therefore easing the temperature of the water in the coil, then manually work the 3 port valve to allow any released air to get to the AAV?

Possibly, worth a try! But I think it’s difficult to rush the process, I think it will just take some time for the water to become deaerated. I’m not an expert on this!

I’m no expert either. I’ve found the best way is to work round all the radiators and bled them. You then get to identify the ones that always seem to get the trapped air. So then concentrate just on those. I have 2 rads upstairs which always had a quantity of air trapped in them. Every few days I have been bleeding them and getting the air out of them.

I don’t believe there’s a quick win here otherwise it would be a standard operating procedure for heating engineers. My engineer simply said, run the heating and hot water, keep swapping between the two functions and keep bleeding until you’ve got out all of the air.