Hi,

I am not electronics specialist so read with caution please.

I have purchased RPICT3T1 RPICT3T1 - lechacal (faq zttp://lechacal.com/wiki/index.php?title=Frequently_Asked ) and sct-013-000 in hopes to measure my whole house electricity usage and once I know its accuracy by comparing to electricity meter, place it on the circuit used by air heat pump system and see what is my percentage is actually used by heating system and at what times.

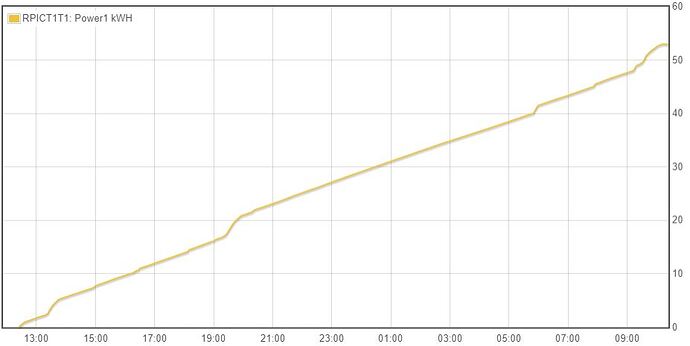

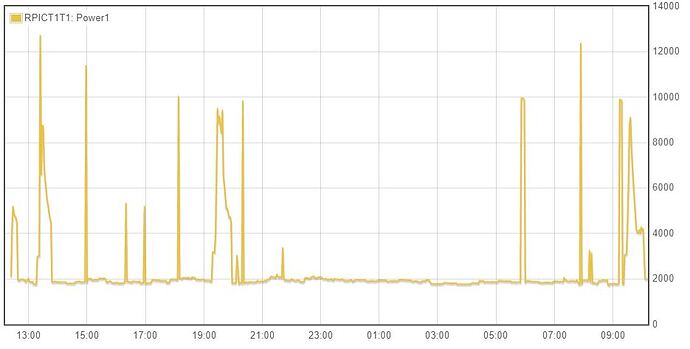

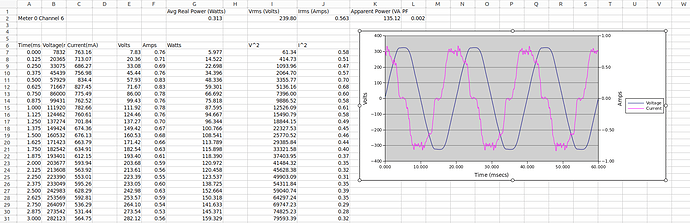

I placed sct-013-000 on my house main incoming live cable before it goes in the circuit breaker, inside AC distribution box (outer casing was touching another live cable that was connected at the same breaker input). But my readings in kWh are way off the electricity meter one, emoncms with sct-013-000 = 53 kwh and electricity meter = 8kwh for ~20 hours. Attaching kWh and Power graphs screenshots.

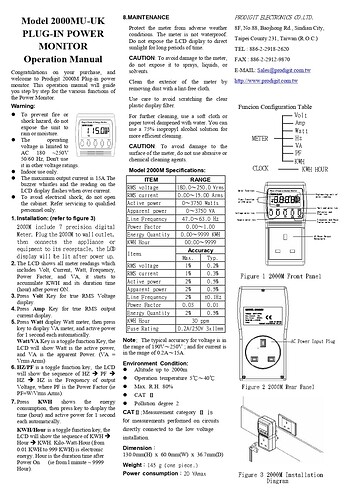

Before installing sct-013-00 on main incoming live cable I did some tests on smaller appliances using plugin watt meter “MODEL 2000MU”, attached is the manual, not sure about its accuracy but at least rough idea. From what I see is that watt meter VA value is close to RPICT3T1 value.

Tests

Computer, Watt meter readings: 53VA 46W 0.22A 0.05kWh RPICT3T1 reading: 59.71W 0.06kWh

Hoover at medium setting, Watt meter readings: 1679VA 1062W 7.17A , RPICT3T1 reading: 1722W

Hoover at max setting, Watt meter readings: 2003VA 1903W 8.8A , RPICT3T1 reading: 2056W

My Setup

I connected RPICT3T1 to old “raspberry pi b” serial pins and installed emoncms using zttps://raw.githubusercontent.com/openenergymonitor/EmonScripts/stable/install/init.sh on it and it is capable of reading values from serial port after editing emonhub config by replacing node 11 with

[[11]]

nodename = RPICT1T1

firmware = RPICT3T1_V1_1.ino

hardware = RPICT3T1

[[[rx]]]

names = Power1,Power2,Power3,Temperature

datacode = 0

scales = 1,1,1,1

units = W,W,W,C

and replacing [[RFM2Pi]] interface with

[[SerialDirect]]

Type = EmonHubSerialInterfacer

[[[init_settings]]]

com_port = /dev/ttyAMA0 # or /dev/ttyAMA0 or/dev/ttyACM0 etc

com_baud = 38400 # to match the baud of the connected device

[[[runtimesettings]]]

pubchannels = ToEmonCMS,

Inputs were created automatically just needed to create the “process list setup” entries, “log to feed” and “Power to kWh”

RPICT3T1 is sending its information every 2 secconds

2022-09-22 10:35:49,217 INFO MainThread EmonHub emonHub (emon-pi variant) v2.2.6

2022-09-22 10:35:49,231 INFO MainThread Opening hub...

2022-09-22 10:38:23,781 INFO MainThread Logging level set to DEBUG

2022-09-22 10:38:23,792 INFO MainThread Setting emoncmsorg senddata: 1

2022-09-22 10:38:23,794 INFO MainThread Setting emoncmsorg sendstatus: 1

2022-09-23 00:15:29,819 DEBUG SerialDirect 1416 NEW FRAME : 11 59.51 7.13 7.87

2022-09-23 00:15:29,824 DEBUG SerialDirect 1416 Timestamp : 1663888529.818701

2022-09-23 00:15:29,826 DEBUG SerialDirect 1416 From Node : 11

2022-09-23 00:15:29,829 DEBUG SerialDirect 1416 Values : [59.51, 7.13, 7.87]

2022-09-23 00:15:29,832 DEBUG SerialDirect 1416 Sent to channel(start)' : ToEmonCMS

2022-09-23 00:15:29,834 DEBUG SerialDirect 1416 Sent to channel(end)' : ToEmonCMS

2022-09-23 00:15:29,956 DEBUG MQTT Publishing: emon/RPICT1T1/Power1 59.51

2022-09-23 00:15:29,961 DEBUG MQTT Publishing: emon/RPICT1T1/Power2 7.13

2022-09-23 00:15:29,966 DEBUG MQTT Publishing: emon/RPICT1T1/Power3 7.87

2022-09-23 00:15:29,972 INFO MQTT Publishing 'node' formatted msg

2022-09-23 00:15:29,975 DEBUG MQTT Publishing: emonhub/rx/11/values 59.51,7.13,7.87

2022-09-23 00:15:31,778 DEBUG SerialDirect 1417 NEW FRAME : 11 59.55 7.63 7.64

Calibrating clamp output:

• Calibration VCAL ICAL PHASECAL - lechacal

• Formula for calculating kcal value “newICAL = ICAL*Ireal/Imes”

• RPICT3T1 “kcal = 26.67 1. 1. 26.67 1. 1. 1. 26.67”

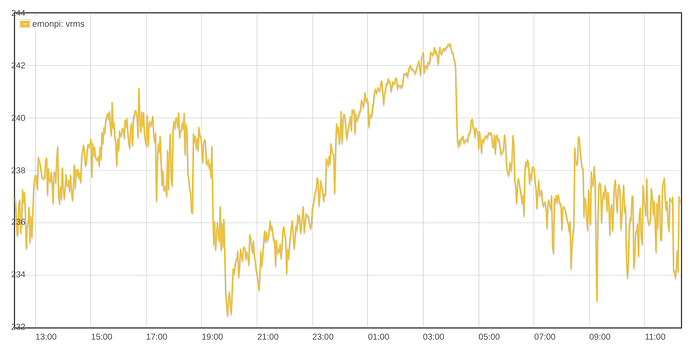

• Output is in watts and there is a constant voltage variable of 240v in config file of RPICT3T1(voltage on my watt meter is ranging from 232-241 when on load), e.g. 1070.30 6.91 7.17 which shows that ct1 shows 1070.3 W

Questions:

- What information should I provide in order to better understand the problem?

- Is it the problem with rpict3t1 and sct-013-000 providing inaccurate information or wrong emoncms configuration of input feeds?

- Am I correct in thinking that VA value of my watt meter is the measurement value that my electricity meter is using to calculate kwh, or is it watt on my watt meter?

- How accurate should VA be to my house electricity meter in kwh, providing that rpict3t1 uses estimated power due to fixed 240 voltage, rough estimates ~80-90% accuracy?

- Should I be using “kWh accumulator” instead of “Power to kWh”?

P.S. Had to replace http urls to zttp.

Thank you in advance