Hi All,

I’m trying to think about how best to represent the amount of hot water I have in my tank and over time use that information to decide if I should adapt the settings I use for DHW. I’m using Home Assistant to collect and visualise the data. I was wondering if others on this forum had done something similar or had different approaches to this? I’m assuming this is better suited to a post here but could also post on the HA forums if people feel that would be a better place for this question.

My idea is to use the information on https://energy-stats.uk/hot-water-cylinder-sizing-and-mixing/ to calculate the amount of “useable hot water” available. To quote from the original blog post by @Zarch for ease of reference:

(MixTemp – ColdTemp) / (HotTemp – ColdTemp)

e.g. if ColdTemp = 10, HotTemp = 60, MixTemp = 41

(41 – 10) / (60 – 10) = 0.62 [i.e. 62%]

Finally cylinder size x 1.62

So 150L x 1.62 = 207L of usable water at mixed temp

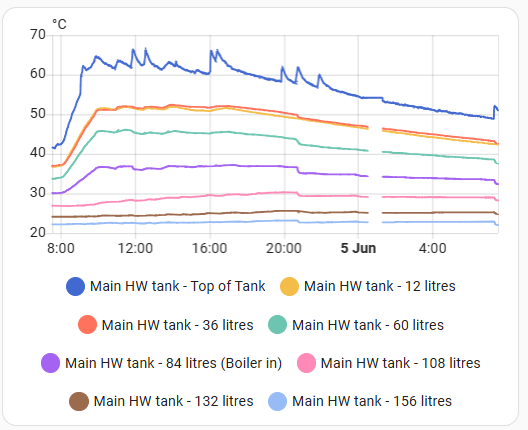

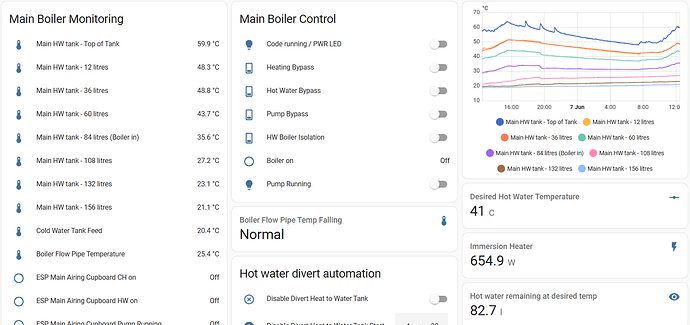

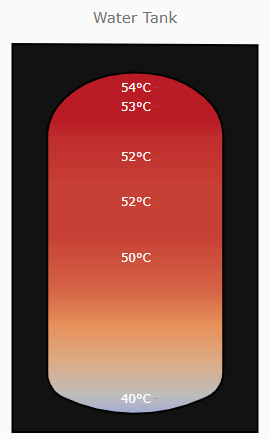

I’ve created a template sensor in HA to calculate my “Useable Hot Water” (I used two number input templates to define the ColdTemp and MixTemp so I can change them if I can work out what the appropriate values are for my home, but for now I stuck with 10°C / 41°C). In my case I’ve got a 300L tank and I’ve just hardcoded that figure in the calc. I wasn’t sure which HotTemp would be best. I have a “Hot Water Top” (top of tank sensor) and “Hot Water Charging” (mid tank sensor) so I’ve conservatively used the “Hot Water Charging” value.

The calculation gives me a value in litres but I think the next step would be to convert this into a more “meaningful” unit for my family. I was thinking of creating an artificial “showers” unit and then (once I figure out the average flow rate - tips for this on the blog - and average length of time the showers in my home) I could convert the “Useable Hot Water” value into say “5 showers”. I’d understand this to mean I had enough water for 5 average length showers, which could also mean 3 “normal” showers and 1 of my wife’s “I’m washing my hair” showers. I’d show this on a gauge with RAG colours showing what we have left in the tank. In time I was also thinking of adding a button which when pressed would override the blocking schedule and top up the tank temperature. This would give us the ability to request extra water heating only when we need it (e.g. after an evening gym session) rather than on a predefined schedule.

Thanks in advance for any tips and guidance. I’ve been amazed at how active these forums are and how helpful and knowledgeable folks are on here!

Samir