I installed the MHRV mainly to head off any damp issues which might be potentially revealed by the insulation which is 50mm PIR foam on the inside of the 9 inch solid walls. which I did as a DIY project one room at a time. . As I did all the ventilation installation work myself also I have no idea what the cost might be if you got a contractor in but my MVHR worked out at about £2000 in 2015 for the unit and all the pipework. The are a number of advantages including not needing any noisy bathroom extractor fans as the extract for the MVHR unit is in the two bathrooms and the kitchen and of course no trickle vents on the windows. It silently delivers fresh warmed air into the bedrooms and living room. For a high open plan I would consider Punka fans as they are extremely good at dissipating temperature gradients in high spaces at very low cost and feel nice in summer as well. You will probably find you can drop the thermostat a degree or so with one fitted as your heat is no longer all hovering round the high ceiling.

A quick, easy experiment - would be to remove all the actuators in the manifold - so all UFH pipe is definitely open, all the time.

And see if that causes more heat to get into the house.

It would rule out anything like thermostats stuck etc: and give evidence to prove/disprove the assumption that:

None of the thermostats in our house currently ever get up to temperature so I don’t think any of them are shutting

Not 15 degrees: up to 30 is possible. The default is 10, which is rather conservative, so I’d go larger than that, but keep an eye on it: as a rough guide, on a 170 litre tank, a sensor temperature of 30 can mean there’s enough for a shower but not a bath.

I see the picture of the UFH manifolds, looks nice. Agree with another commenter about checking that the mixing valve is not limiting the temperature going out to the UHF loops. Generally UFH loops should work good at lower temps.

However, UFH loops need to be constructed well to transfer the heat into the floor. Could you post some pictures of the typical UFH setup?

Are some of them pex tubing in a mortar bed? (can’t too wrong, unless lots of carpet on top) Is it ‘staple up’ tubing under wood floors? Are there aluminum heat dissipation plates around the tubing or is the tubing just under the floor, with or without insulation underneath. (many ways to go wrong here)

As mentioned elsewhere, the mixing valve limits the temperature of the water into the UFH.

What does the temperature gauge read, so what is the UFH set to? Mine runs at about 35°C The TRV (with an external temperture sensor) opens and closes to control the heat (same as a radiator) adjust it, and the heat to the UFH rises.

Assuming this is connected directly to the HP, I’d suggest there is little point having the HP Flow at a greater temperature than the floor temp (if that is all it supplies).

All you needed to do was fully open it!

Are all the flow meters showing flow? You pop the red collar up and then turn the black bit underneath to adjust the flow. You need to experiment what flow works best. I had some air in my system initially which shows up by one of the flow meters not indicating flow. Turn off all the others to try and force it, else you need someone to flush it through.

Sadly, that looks highly possible.

legionella is aerobic bacteria a hotwater tank is anaerobic condition it can not grow in there . if your water comes from a treated municipal source or ground water source ( anerobic again) legionalla can not grow in this condition … if you use a cistern or get your water untreated from a lake pond or river then you have higher probability of legionella

Yes, but if your DHW is heated indirectly (i.e. the incoming water passes through a coil in the tank to heat), the risk is pretty much non-existent in a domestic environment.

The risk is only present if you use the same water that is actually heated by the HP.

Again it is entirely aneorobic conditions. At no point is the water stagnant and open to the air or highly oxygenated water. My entire hydronic system runs on fresh water, untreated ground water, and part of a DWH system - consist of two tanks, DWH (primary ~30 gallons) and secondary preheat heat buffer tank. (~75 gallon that’s connected to the hydronic heating system as well as the DWH) both heated to 45-48C by heat pumps. Legionella bacteria can not survive or reproduce in a low oxygen environment. If so, I would’ve been dead or sick of legionella decades ago. The only point the risk of legionella bacteria is high with a HP is when used for cooling and the condensation on the outside of the heat exchange coils does not drain away properly. Legionella can develop in this stagnant water and be aerosolized by air movement and infect the occupants. When speaking specifically of DWH concerns, the stagnant water that is trapped between the tap and and your shower head and/or in the loop of the shower head hose is where legionella would develop - not within the waterline system before the tap. (unless you get your water from a cistern, untreated lake, river or pond as they are open air, i.e. oxygenated and stagnant )

If you are not heating as warm as you like, it seems that your floor radiant temperature is not hot enough to compensate for your heat loss and can not keep up. From your original graph it seems to be set at ~25C. I would turn that up to ~30C. You already adjusted the hot water temperature down so the heat pump run cycles are shorter. You can also adjust the HP temperature differential. It probably is ~2C currently. I adjust mine to 5C differential (and you can adjust you temperature up again if you like) It will extend the off period between run cycles and the run cycle will be longer, but that reduces the overall number of off/on cycles which will improve the overall efficiency. It takes generally about 3 minutes for hp pump to reach peak efficiency when it first starts, so if you have less start cycles you have higher overall efficiencies. You can also force the wait period between restarts (currently it’s probably set at 1-3 minutes) I have mine set at max. (15 minutes) That reduces wear and tear on the hp mechanics as it allows the pressure to equalize so there less stress on the HP when it starts and also forces longer run times which in turn also improves efficiency.

I bet you won’t get much change out of £300.Your Heat loss calculations are all wrong need re doing £200: When it’s all done can you put up what you paid and the results.Heat Geeks are the kiddies right enough

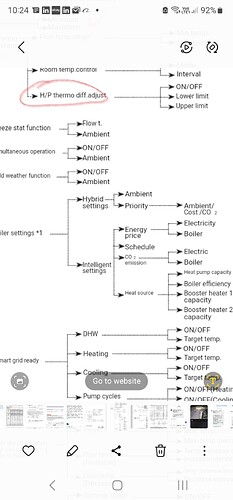

How can you do this exactly?

every heatpump is different . so it hard for me to say where it might be on your heatpump. usually you can find them in the service/system settings , hopefully your heatpump not locked as alot of installers do that so you are force to to use thier service as they are they are the only ones who know the password to enter service menu. in the case of my heatpump i hold “set” button for 5 seconds then it goes into service/system mode then I can adjust all the heat pumps settings – easiest way to figure out if your heat pump is locked .when or if you ever got an error . if you heatpump is disabled until servicemen comes, then most likely it a locked system

looks like that could be it , with out seeing what the start header was called