One of the key criticisms of HeatpumpMonitor.org that I often hear is that SCOP does not necessarily reflect low running costs, or total cost of ownership. Some have even suggested that by encouraging optimising for SCOP among installers and customers we could actually be doing the industry a disservice that could hold back wide scale adoption!

That’s certainly an uncomfortable suggestion given that part of the intention behind HeatpumpMonitor.org is to show with real world data, not sales, how well heat pumps can work if installed, designed and commissioned well and that this should help increase confidence in the technology, aiding adoption.

Many have made the case that it is total cost of ownership that we should be optimising for. SCOP is just one variable alongside the price of electricity, installation cost and other factors. This does of course make total sense, though it does get more complicated to measure and define!

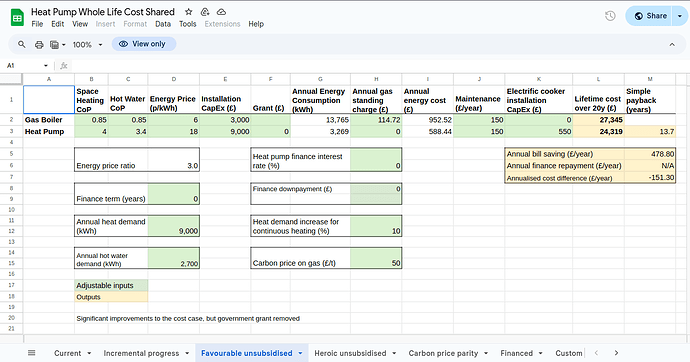

A while back Lewis Bowick who works at Energy Systems Catapult, shared a heat pump whole life cost calculator that is a great starting point for exploring this question. This calculator can be accessed here: Heat Pump Whole Life Cost Shared - Google Sheets (Lewis has shared this in a personal capacity, this is not an ESC work output).

The tabs at the bottom give different examples, current contex, unsubsidised, financed etc:

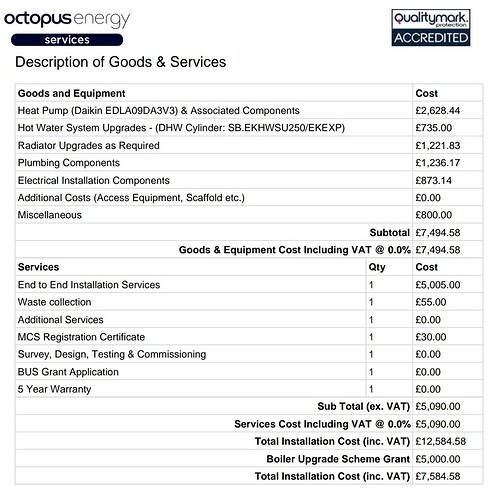

I think it would be great to extend this tool to breakdown installation cost into:

- Cost of outside unit

- Cost of hot water cylinder

- Cost of any pipework and radiator upgrades

It would be great to allocate labor based on these categories and include an estimate for replacement lifetimes.

When would the gas boiler comparison case require replacement pipework and radiators and how does the cost of upgrading that compare at that point to a lower temperature system?

The cost of equipment also varies considerably by brand, A samsung gen 6 costs about £2k, A vaillant ~£4k and a Viessman around ~£6k I think. How does longevity vary and long term servicing costs? The cost of labor, the amount of time and attention to detail given to the project and service level also varies by installer. How do we avoid boiling everything down to an oversimplified installation cost with a race to the bottom. The amount people decide to spend on cars for example varies significantly based on make/model/brand even if in a basic sense they all do the same job…

Should we include a form entry option for installation cost on HeatpumpMonitor.org? I wonder if we could explore a couple of examples in this thread before we do that. E.g installation cost, running cost and SCOP and the interaction between these?

My own example is complicated by the fact that I did the work myself and didnt count how many hours I spent installing the system ![]() Equipment cost was ~£4.8k in 2017 (5 kW Ecodan £1.8k, Cylinder £1k, Radiators and pipework ~£1k, other bits ~£1k) I get a SCOP of 4.1 and unit cost of heat last 12 months of 4.4 p/kWh (18 p/kWh electric).

Equipment cost was ~£4.8k in 2017 (5 kW Ecodan £1.8k, Cylinder £1k, Radiators and pipework ~£1k, other bits ~£1k) I get a SCOP of 4.1 and unit cost of heat last 12 months of 4.4 p/kWh (18 p/kWh electric).

I explore in my blog here https://trystanlea.org.uk/original-heating-system how the annual saving from upgrading my radiators (without which my SCOP would probably have been ~3.4) likely makes for a surprisingly long payback, e.g only a saving of £84/year or £1680 over 20 years. At some point a radiator system will need replacing anyway and the cost difference in going for a low temperature system at that point will of course be much lower! Understanding the point at which that needs to happen and taking that into account is probably a key part of this question.

Hopefully this is useful as a starting point for a discussion, it would be great to explore what we could do as part of HeatpumpMonitor.org to provide more insight on total cost of ownership and how to balance SCOP/SPF against the other factors.