It all started a number of years ago when I decided I wanted to heat my pool with a heat pump. After some investigation I discovered how to convert a pure cooling split aircon into a heating (only) machine. I built my own coil heat exchanger and installed it where it has now been running for a number of years. It didn’t have any sort of control system (and still doesn’t) but works very well.

Following on from that I decided to add a heat pump in series with my oil boiler which at that time fed radiators (iron!). I upgraded and enlarged the radiators to aluminium and started developing a controller for the heat pump. Originally I was using a PIC processor but it was limited on memory etc… so I then changed to an Arduino Mega. Much better until along came the ESP8266 with WiFi and all.

The heat pump(s) that I have are from old mini-split systems. They aren’t inverter, just on/off compressors. I did hack a Daikin split inverter but it’s a huge challenge when there is absolutely no published information. I did get a very basic controller working with the Daikin but as I can’t rely on the machine lasting indefinitely it seemed an excessive effort that may later be wasted. So I decided to stick with the non-inverter machines. As I install air conditioning systems I regularly obtain old machines so have a reliable source.

As I said, the controller uses an ESP8266, the -12 which has plenty of memory but is a little lacking on I/O so I designed an expansion board with I2C parallel I/O and analogue inputs (for temperature sensors).

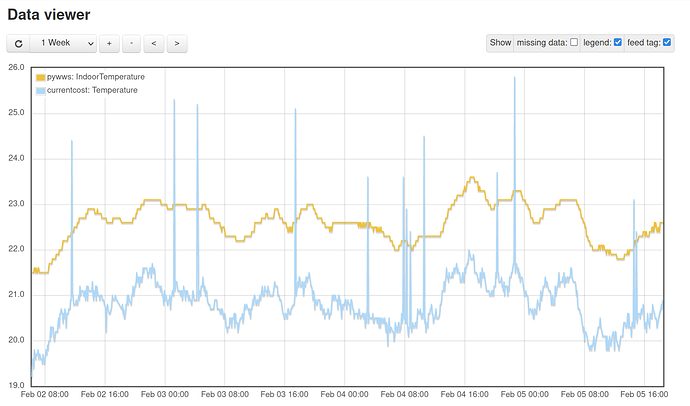

One of the interesting challenges of the software was developing the auto-defrost algorithm, it took a couple of years to perfect it but it’s now working a treat. Typically heat pumps have freezing problems around 5 to 6 degrees C but not always - it depends on the dew point.

Initially I used my own coil heat exchanger fitted inside a 100 litre hater heater. Later (when one happened to become available) I upgraded to a plate heat exchanger - I now have 2 machines, each with their own plate heat exchanger, connected in series.

After running the heat pump with radiators for a couple of years we did a renovation on the house and so as part of that I installed underfloor heating (all our floors are concrete slabs).

The (huge) plus side of underfloor heating is that I can use it in the summer for under floor cooling - something that radiators can’t do. For anyone without the option of changing to underfloor heating/cooling you could use a fan-coil although I don’t have experience of them.

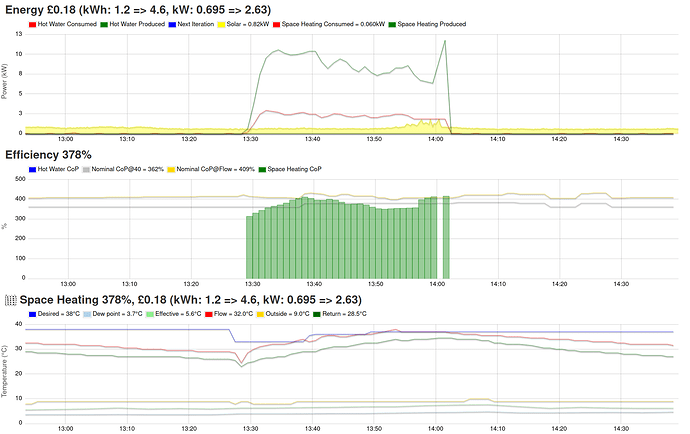

As part of my controller I have added a web based interface for programming/monitoring and also an android app that connects via MQTT so I can control the machines remotely.

There’s loads of information on the ecorenovator.org website, including more details/photos of my build - just search for posts under my name, Acuario.

At the moment, no I don’t use emoncms but you never know, I might add it.

And no, I didn’t build the system for any government incentive (where I live in Spain I don’t think there are any…). I built it all because it was (and still is) a fun challenging project to do. If you discount my time, it has probably cost me less than 500 euros to build as almost everything is recycled.

).

).