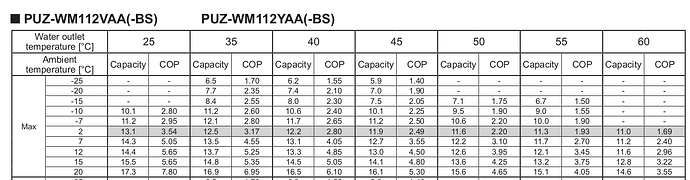

I’ve spent some time figuring out a better way for estimating how much power the heatpump draws. I started with the performance data from Ecodan_ATW_Databook_R32_Vol5.3_.pdf that shows the Max* Capacity and COP:

(*“Performance at Maximum compressor frequency”)

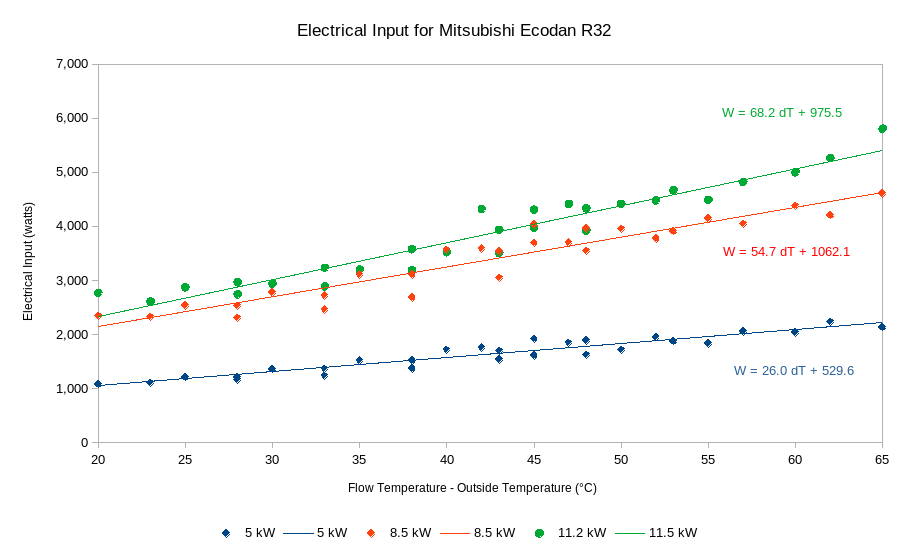

Capacity ÷ COP gives me the input power in kW. Plotted as watts against Flow Temp - Ambient Temp is very nearly linear. I ignored values below -10° and above 15° as these didn’t fit well and aren’t typical for UK climate. I also ignored 2° ambient as that includes defrosts, and omitted 25° flow.

The trend lines fit with R² of 0.9, and give us formulas for each of the three models I looked at:

(I did look at fitting a quadratic instead, but the end result wasn’t much different)

- 5 kW -

26dT +530 - 8.5 kW -

54.7dT +1062 - 11 kW -

68dT +976

From this I was able to work out the following formula implemented in a virtual feed:

- Flow temp - Outside temp

- × factor for model, e.g.

68 - + offset for model, e.g.

976 - × HeatPumpFrequency ÷ maximum frequency¹

- + 250 W if compressor is running²

- + 100 W if primary pump is running³

- + 20 W for standby power

¹ max frequency possibly different for each model, I don’t know. 110 Hz for my system

² I guess this is for the big fan and other things going on when compressor is running

³ pump power probably depends on the speed setting…

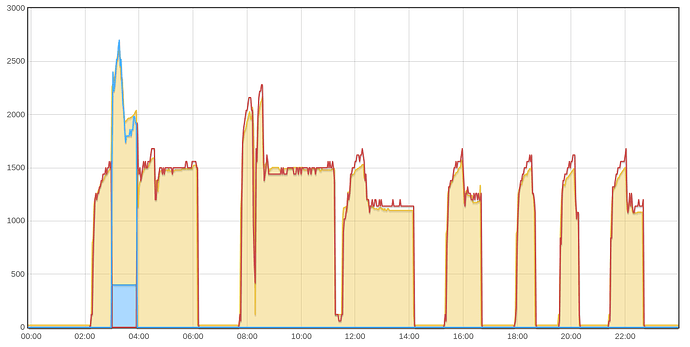

Here’s measured vs. estimated for my system on Dec 14th:

Yellow is the estimated power, red is the measured power for heating, blue for hot water.

I’ve had to add an extra 400W for the DHW pump, which seems excessive but is what fits.

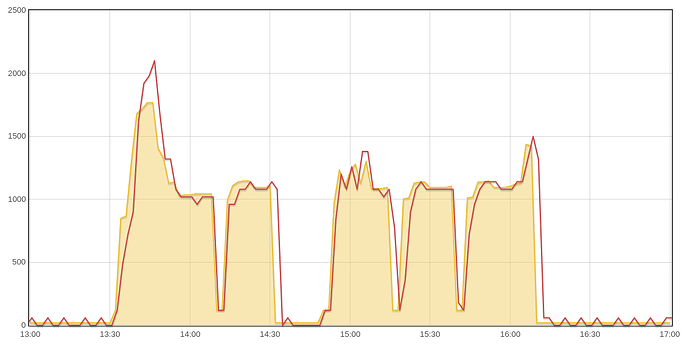

Same formula running on another 11.2 kW system shows it matching just as well there too: