Hello @designerguy

Your system is an interesting example of what a simple approach can achieve. I’ve been following along on the various threads you have contributed to, where you share different insights but wanted to bring some of the key stats together here for easier reference:

- Samsung HTQ 8kW (~approx £3.9k for the heat pump).

- Weather compensation setting:

- 50C flow temp @ -2C outside

- 35C flow temp @ 15C outside

- SPF 3.2 (from the Samsung display)

- Standard 120 L indirect hot water tank (flow temp peak 68C)

- Vented system with header tank

- Pipework: 28mm to hot water tank, 15mm elsewhere

- 4 bed detached brick, with modern extension (cavity filled). Double glazed, 300mm loft insulation.

- Previous system: Oil boiler (18kW Wallstar, 25 years old)

- Previous oil use: 1500 litres/year, £1200/year @ 80p/litre

- Oil use on coldest day 12 litres (heat pump uses ~40 kWh electric on coldest day, 2.5 cop, 18C internal temperature?)

- Secondary heating: Log burner

- MCS installer quote: £15k (included new cylinder, pipework & plant room? did it include radiators?).

- Self install costs <£5k?

Using these figures suggest:

- 12 Litres oil on coldest day = 124.2 kWh @ 80% efficiency ~ 100 kWh heat = 4.2 kW heat demand.

- 40 kWh electric at COP 2.5 = 100 kWh heat = 4.2 kW heat demand.

- 1500 L/year = 15525 kWh / 2.8 (Podesta capacity rule of thumb) = ~5.5 kW

- 50C flow temperature at -2C and 4.2 kW heat demand suggests a rated radiator capacity of 8.8 kW @ DT50

- 7 Litres/min minimum flow rate from the datasheet suggests minimum heat output ~2.4 kW, 30% minimum modulation on 8 kW (mid summer capacity graph at 50C flow temps).

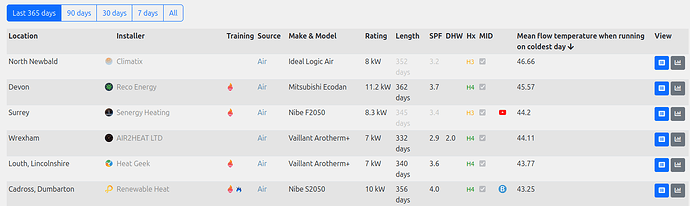

We don’t have any systems yet on HeatpumpMonitor.org with average flow temperatures of 50C on the coldest day, the closest is the Climatix Ideal Logic Air which matches your SPF at a flow temp of 47C (HeatpumpMonitor.org). Would you consider putting full monitoring on your system to highlight your case study, with more detail? @glyn.hudson’s experience of the internal monitoring on this Gen6 samung suggested some fairly large errors Samsung 5kW Gen 6 Air Source Heat Pump Installation with monitoring - #6 by glyn.hudson.

It would be interesting to know if the installer quotes you received included upgrading radiators. It seems that £12-15k quotes without radiator upgrades are not uncommon.

I was quoted £12.5k for the heat pump and hot water cylinder with no radiator upgrades. I installed the whole lot myself in the end for a material cost of £4.7k (£2400 for the heat pump, £1000 for cylinder and £400 copper pipe and fittings, £600 radiators, £300 misc). At the time my over-inflated heat loss suggested my low temperature heat pump would not have been able to run the existing radiator system but I now calculate based on an accurate heat loss that I could have actually run the existing system with no upgrades at a design flow temp of 47C, which technically even my low temp heat pump could supply. If I had realised this at the time I would have tried it, if only for heating science… after a very thorough flush of that older system.

Is the real lesson or point that your making, not necessarily low temp vs high temp, but that it can be possible to install a heat pump in a simple bolt on approach to an existing oil boiler heating system where there is an existing cylinder in place and that with careful tuning of control settings (crucial!) a better SPF is possible than almost 90% of the systems on the Electrification of Heat trial (https://eoh.heatpumpmonitor.org/)!

If there was no BUS and MCS to distort the market, perhaps this type of try it, tune it and see approach would be more common.