Inspired by a comment in this topic I thought I’d share some extreme 1wire testing I’ve been doing. I’ve got 100 ds18b20s spread roughly evenly across two buses (50 on each bus, plus a few extra stray sensors on bus0). I used a handful of these 5x5 testboards:

That particular one is dangling from the ceiling above my desk.

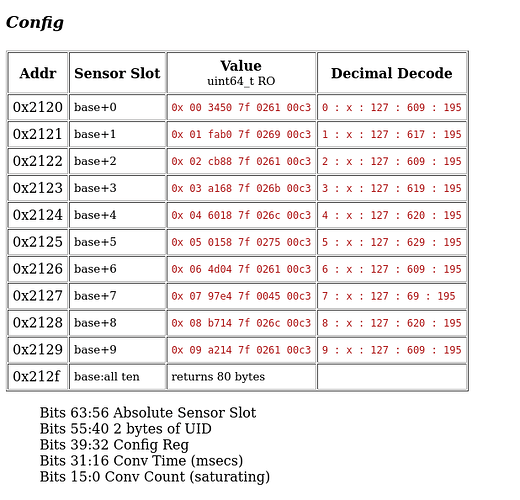

I picked the bottom left and bottom right sensors (slot 51 and slot 48) and confirmed they were in good agreement:

0.48: 0x 30 d4f7 12 0b60 (22.750C)

0.51: 0x 33 93df 10 0b60 (22.750C)

0.48: 0x 30 d4f7 1a 0b78 (22.938C)

0.51: 0x 33 93df 18 0b78 (22.938C)

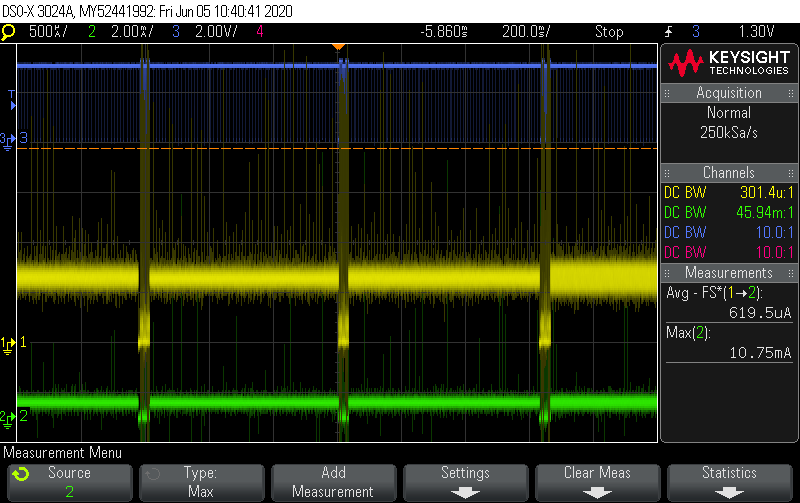

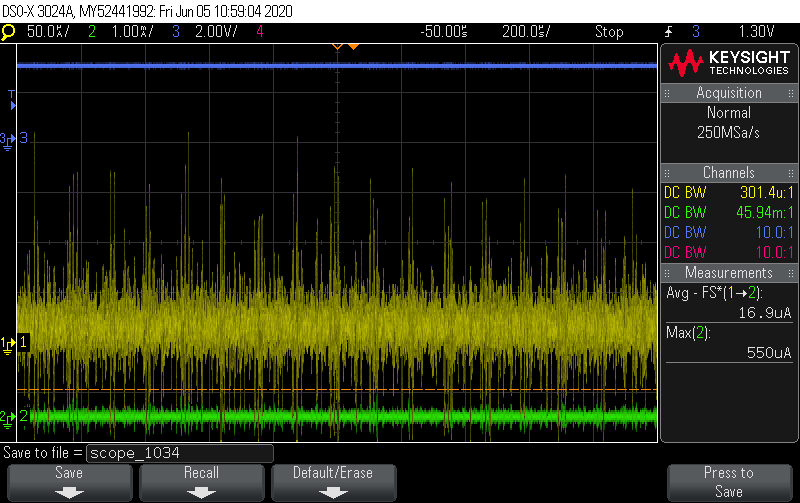

with 12-bit conversions every ~40 secs. Then I changed the code to hammer .48 as hard as possible (back to back conversions every ~620 msecs) while converting .51 once per minute, which yielded:

0.48: 0x 30 d4f7 01 0bc8 (23.562C)

0.51: 0x 33 93df 01 0b88 (23.062C)

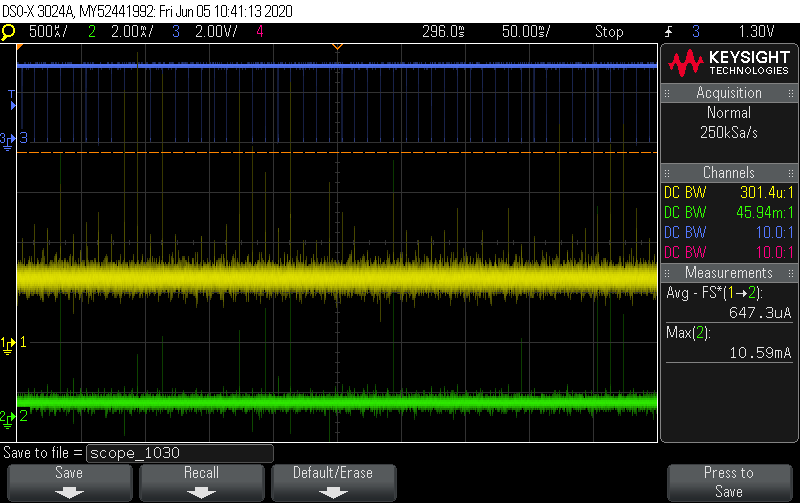

Then I swapped the hammering to .51, with 1 minute conversions on .48:

0.48: 0x 30 d4f7 1e 0b88 (23.062C)

0.51: 0x 33 93df 00 0bc0 (23.500C)

So it looks like you can get about 0.5C warming doing conversions too rapidly. I reduced the hammering rate until they both agreed, and that was at 2 sec sampling rate.

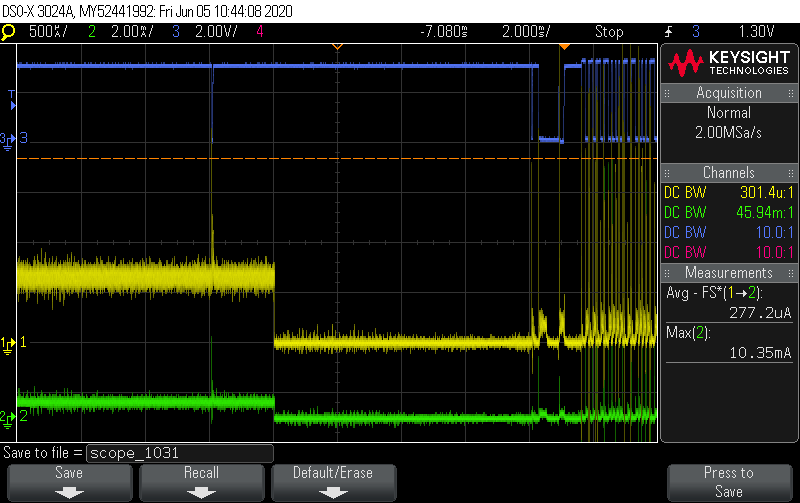

Those components on the testboard are all Dallas genuine, so then I tried an ebay-purchased encapsulated non-genuine. One thing I’ve noticed with all my non-genuine samples is that they do the conversions much faster. They can do a 12-bit conversion in about 89 msecs Vs about 620 msecs for the Dallas parts. The following are the results at ~40 sec sampling, and then back-to-back sampling (~11 samples per second):

0.44: 0x 2c f5db 0d 0b00 (22.000C)

0.44: 0x 2c f5db 00 0b10 (22.125C)

So they’re faster and show less signs of self-heating, although I’m unsure if that’s because they use less power or because the metal tube acts as a heatsink.