I assume you are saying that because my situation is so common, people won’t turn to DIYBMS to handle it. This is a good point. However my thinking is that it won’t be too much effort to make DIYBMS competitive with off the self solutions. This is why I asked Stuart what his goals were?

(If you are assuming my situation is uncommon: I have an RV. This is very common and has essentially the same needs as any off grid home. A single battery bank, solar panels, and an inverter. In both cases the user will want to know the state of charge, and the PV current is nice to have. Also the thing is rather useless without the relays.)

My take is that boards are cheap and that is totally irrelevant because the other costs overwhelm that. Shipping eats a bunch of the cost. The soldering is not cheap for those that don’t have a soldering iron. The surface mount soldering might be no problem, but I am avoiding it. The attiny progamming board needs to be purchased. Making the jst wires is a pain and securing the different boards is a royal pain. All of that affects the cost. When I see some text mentioning how cheap the parts are, I roll my eyes.

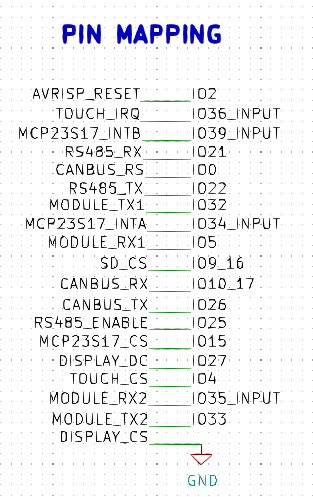

So my opinion if the goal was to have just one controller board, why not one like this? The 2x INA226 chips are a whopping $1.30 each, and the 3x TLC226 opto relays don’t have to be installed. In other words, so what if some users don’t want the current measurement and relays? This design can function identically to the current controller board, and it can measure current and also has 6x relays.

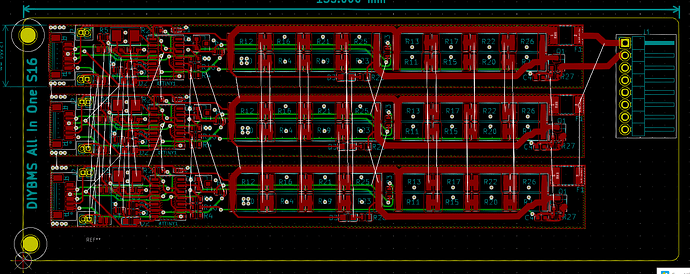

But, I see no point in just one option for the controller board. The Leaf module boards are an excellent example. I am going to make a single board that has 8x modules and the controller. This will eliminate all the daisy chain wiring and make it so that I only have to mount one board. Why not have a release that has 4x modules for a 12v system?

In order to reduce dumb questions the project has to be obvious. I found the jlcpcbassembly branch not obvious at all. I managed to figure out how to order the stuff, but later found the videos on how to do the ordering. My impression is that the videos are no small production matter.

If the idea of more than one controller option and the controller/module combo is reasonable, then I would organize the folders like so:

Controllers

Modules

ControllerModuleCombos

Under each of those top level folders there would be additional folders for the different variants.