David, I have received your PM, thank you. I am very happy with what you have suggested.

However, today’s drama is I walked up a mountain path today on my day off in driving rain and wind. Although I thought my iPhone was protected enough inside a pocket, this was not the case and I currently have a dead iPhone. I really could have done without this.

Regarding drawings, here is a pdf which should show you enough. If Recall, one of the temp sensors altered its position slightly, not the main cylinder one (there is not one on each cylinder, presumably because with an equal drawdown, it is superfluous). I will have to check with Sally which one

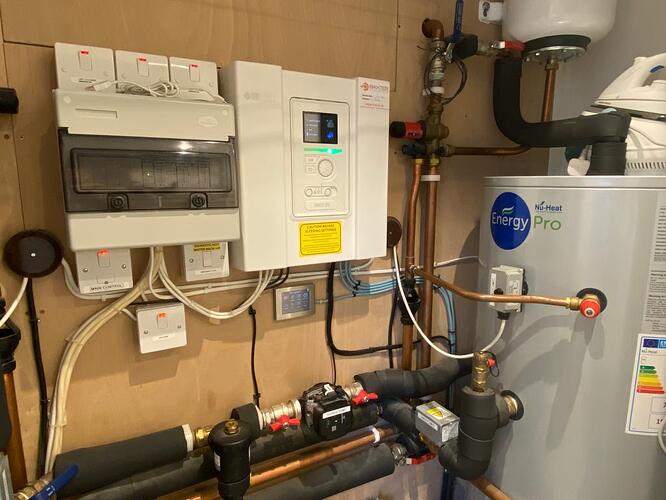

C21 v16.pdf (2.2 MB)

Good morning David

My partner Sally has navigated to menu 4.2 and selected manual, deselecting the two options within that sub menu. If I am correct, think the “add heat” allows the software to bring in external components, e.g. the immersions, to help with a demand when the compressor cannot meet the requirement. I remember Christmas Day before last when we had family and a lot of showers , the immersions came on to help. So our 24 hour data from today may show a reduction and help to narrow down the problem. Fingers crossed.

Precisely - in NIBE terminology, “Add[itional] Heat” refers to resistive heating elements that typically get brought into play when the vapour compression cycle is failing to either keep up with heat delivery or to get hot enough. I normally keep those options ‘blocked’ (i.e. turned off) but with a single 200 litre DHW cylinder and some relatives that like their showers 10 degrees hotter than I do, family visits can drain the DHW tank quicker than my 8kW heat pump can keep up.

For Tim and others following this thread, Peter and I have been exchanging private messages and I’ve hooked his system into my own monitoring scripts.

The current situation is that:

- The heat pump’s “Operating Mode” has been set to "Manual’ (via menu 4.2) so it’s not even trying to do any space heating but it still heats the stored hot water.

- It did a hot water cycle overnight

- We’re going to see what happens to the electricity consumption in this configuration.

- Hopefully that consumption will come right down

- When we let it do space heating again, there’s monitoring in place to graph the flow and return temperatures through the buffer tank

Thanks to Tim and David’s efforts and help, I believe there is some light ahead. The switch to manual was made roughly mid morning yesterday and the 24 hour KWh reading (done by Sally at about midnight daily atm) was 6KWh for the period of Sunday and she did a quick reading just now at 09.00 and it was only showing an extra 1Kwh in 9 hours!

I think we need a couple more days of this sate where the buffer tank is not being warmed to provide more evidence.

Excellent; that is indeed good news. 1 - 2 kWh is much more what we’d expect as the electricity consumption to reheat the DHW tank each day.

If we can get 2 - 3 days of baseline readings of consumption just for DHW that will provide a good basis for comparing what happens when bringing the UFH and the Buffer Tank back into the mix.

Absolutely; we will take daily readings.

I agree with the thoughts about tank insulation (whether it is sufficient).

FWIW: Our household water heater has been using about 8 KWh per day for the past week.

This is a standard resistance-electrical heater, 50 gallon size residential unit.

No additional insulation; just the factory stuff (AO Smith).

Family size = just my wife and I; I think we probably use somewhat below average hot water consumption.

Environment = water heater is in the garage, which has been averaging about 55F = 13C recently.

I’m not sure how helpful this is, but it’s one more data point suggesting your heat pump consumption is indeed too high.

Agreed it is worth paying for 1yr of NIBE uplink to try and diagnose what is happening.

The past three days of ASHP KWh have been; Sunday - 6 (we only switched to manual late morning), 3,3,4 (Wednesday). That is an acceptable amount I think for 2 x 200L of DHW, even though not much is actually being consumed over those days. I believe it is only set to 44d. I am in “normal” mode on the SMO20 controller, perhaps for single occupancy I could switch down to “economy”. But either way, in the ball park.

However, I do now need to reintroduce the heating element. Although I said previously our “UFH” does not really contribute much, my partner is saying downstairs has dropped in temperature and I can see from my automation that the loop is running more (living area average temp is about 1d down which has taken it below the 20d threshold where the pump starts to circulate), but of course it currently has no heat to harvest from the buffer tank. The issue I believe I have is that, whilst the house is good at retaining warmth, it has a very small heat demand but the ASHP keeps producing warm water in the buffer tank that the loop does not require. When we turn the unit back, the loop will do its work , the house will be back up to temp and the loop will stop. But the buffer tank appears to keep on assuming more is required. The curve is currently at 6 in NIBE terms. that is a curve which equates to 34d flow temp at 0d outside temp. The installation started its life at 3, which is 27d flow temp at 0d outside. This adjustment was made because it appeared the ASHP was doing a lot of short runs starting and stopping, so the increase was deemed by an engineer to be a way of smoothing out the on/off cycles. Obviously when we turn the heating back to auto, the electricity consumed will probably return to previous, unacceptable levels. It is trying to find a method to join up the two systems. On a sunny winter day, solar gain achieves a lot and the house is warm. It is a useful coincidence that the past three test days have been grey and miserable, although outside temps have been several degrees above zero, even at night. I now realise that my UFH loop has potentially contributed more than I previously thought, but it still remains a set up that does not require much and the buffer tank is working too much. I could reduce the curve; there is actually a manual setting but I would not be sure what figures to enter. Whilst mostly the perceived wisdom is to leave an ASHP on all the time to sort itself out, is this scenario better suited for timed slots? Any thoughts?

Is the buffer tank, HP and UFH all using the same fluid, or is there some form of heat exchanger (a coil for instance) in the buffer tank to separate the UFH fluid from the HP fluid

At what temp does the Thermistor (where is that sited/what is it reading) tell the HP to fire up (should be somewhere around the UFH flow temp)? How long, from the lowest temperature, to being full does it take the HP to heat the Buffer tank.

I think weather comp is the wrong route. Simply turn on the HP when the Buffer tank gets to X°C. It will run until full (need a temperature sensor at the top and the bottom). I’d suggest a dump valve so no new water enters the buffer tank until the flow from the HP reaches a minimum temperature (else you get a cold slug into the buffer tank).

[edit]

I am presuming here that the UFH manifold has a mixing valve to control the temperature of the water flowing into the UFH.

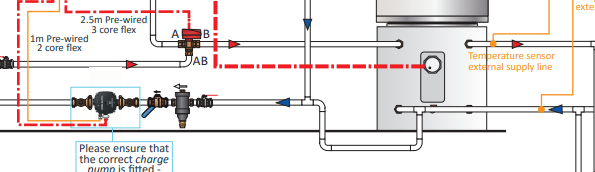

It’s not evident that there’s any integration between the heat pump and the UFH controller - i.e. I don’t see any ‘Call for Heat’ signal to the ASHP from the UFH in the PDF Peter pasted with some plumbing and wiring diagrams 5 days up the thread. There’s also no mixing valve shown for the UFH.

I’ve formed a view that the generic NuHeat design isn’t expecting Passivhaus levels of heat demand so it isn’t especially well adapted to Peter’s use-case.

Peter’s currently trying his setup with the UFH target temp set higher that it’s ever likely to achieve, so the UFH pump runs all the time, circulating water at whatever temperature the Weather Compensation on the heat pump decides to generate, and the Flow and Return temps are being picked up by my monitoring, so we’ll see what that shows over the next few days.

@prwv - you might want to consider adding a Room sensor RTS 40 NIBE (I have no experience of that supplier but that’s a handy link to the right bit of kit; should be the same as your existing outdoor sensor) so the heat pump has visibility of room temperature which can be used to tweak its WC logic since - like me - you have the “problem” of passive solar gain on cold-but-sunny days which means much less heat is required than the outdoor temperature would imply, based on the WC curve alone.

I didn’t suggest there was.

@prwv said

Thermistor on what and at what temperature.

The 2 parts (HP to buffer and buffer to UFH) should be independently controlled. UFH controlled by room temp and HP by buffer temp.

[edit]

I’d missed the PDF.

Fundamentally, if the UFH is running and the HP isn’t, there is nothing to stop the return from the UFH going through the HP. I’d suggest this is a flaw. If the HP is off, the circuit should isolate so the UFH water simply circulates through the buffer tank.

There should be a blending valve on the UFH that controls the temperature of the water in the slab. This then slowly drains the stored heat from the buffer until it hits roughly the target temperature of the UFH water temp. HP then comes on, charges up the buffer tank and switches off again when that is full.

There also seem to be multiple pumps working on the same fluid. One ‘charging’ the HP, one charging the top of the DHW tank and one charging the UFH - all operating on the same fluid stream. Crazy.

No it is not the same fluid. As far as I understand, it is working as a thermal store where the mass of the water harvests heat to the coil which is an extension of the DHW loop.

Now this was never envisaged as a space heating source because we did not think that was required. Granted all houses, even a PassivHaus has a heat demand, but we thought ours was minimal. This loop, which was bought by us directly, not a NuHeat purchase was put in as a “just in case” scenario before the slab was poured. I do know cases where people have installed multiple loops and never connected them. Because we were only seeing this as running occasionally and at a very low flow temp of say 25d, we made it a simple, single zone and did not install a TMV on the loop.

However, yes, the two systems are not “joined up” and we have clearly let this rumble on. No excuse, but I am away a lot and not tackled this earlier. Modern electricity prices have severely sharpened our mind! The drawings I posted were all I could find electronically on my laptop out here. They were more for the electrical first & second fix thus the plumbing elements are slightly cut down. The main omission is the second, parallel 200L DHW cylinder.

David has explained above what I am putting in practice short term and I concur that NuHeat did not particularly appreciate the PH demands or requirements.

I subsequently found your PDF I think says it must be.

To solve the issues, I think:

- You need to have a valve on the UFH that limits the temperature of the water entering the slab - this blends the return water with a small amount of water from the buffer tank so returns a small amount of cooler water to the buffer tank.

- A valve to prevent the return from the UFH flowing through the HP unless the buffer tank is below a set temperature

- A couple of sensors to tell you that (the flow temp from the buffer tank should do).

- A fail safe so the if valve at 1 above is closed the Shuttle valve is open to A

When the UFH is on, the water flows though at the HP flow temperature and returns not much colder to the HP and the HP tries to run if the UFH is on, but cycles as the DeltaT is too low.

(I am not a heating engineer - not that that is any guarantee either way!).

[edit]

It does presume you have a separate pump for the UFH as part of the manifold. If not probably change the manifold.

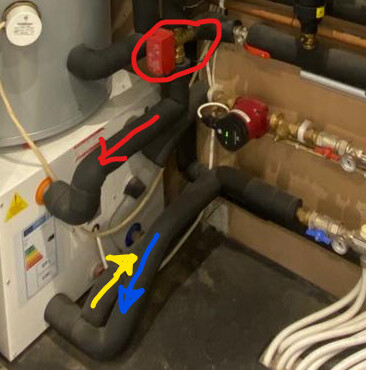

The best I can do in lieu of drawings is this photos that my partner took earlier today. I just phoned NuHeat and they confirmed it was a coil inside, but I see what you are highlighting and will check again

You need to understand exactly how it is setup. If it isn’t as per the diagram, you need to know that and get a diagram of the actual setup, else the rest is just guesswork.

[edit]

Are you sure you asked about the Buffer Tank? The DHW bit will be a coil.

[edit2]

This is the sort of UFH manifold I am suggesting. The valve at the bottom of the pump controls the temperatre of the water entering the UFH pipework

I very much did ask about the buffer tank. I agree you have spotted something that is not how I had always understood. I returned to NuHeat and the man in technical could not explain it either. He, like me , thought they were very much independent sources and the water did not meet, just like a DWH cylinder where the potable water is nowhere near the inhibitor filled water that warms it. I have always been of that view and apologise that I entered into this forum with a misguided idea, although my problem remains! It does look as if the return goes into the buffer as well as the return to the HP. I am awaiting an email to call back to a HP technician because he said, whilst not understanding the reason , " we have always done it in this way" I will update when I know more and I appreciate your ideas above.

A little difficult to tell if it plumbed as per the diagram above. If you can work that out, it would be a starting point.

Blue - looks like return from UFH,

Red - Flow from HP via shuttle valve (circled) to charge buffer tank. Behind red line is flow to UFH

Yellow - if as per diagram, this is return to HP.

Yes I absolutely agree with your arrows.In fact the yellow joins the return from the other cylinder - you can see it just below the UFH return. It looks exactly like the NuHeat drawings so the return from the UFH loop goes back into the buffer tank coil as well as combining with the returns of both HW cylinders. Well spotted, thank you. I am still waiting for an email from NuHeat to let me speak to a HP tech support person to explain this because it is absolutely contrary to how I ever understood it to be.