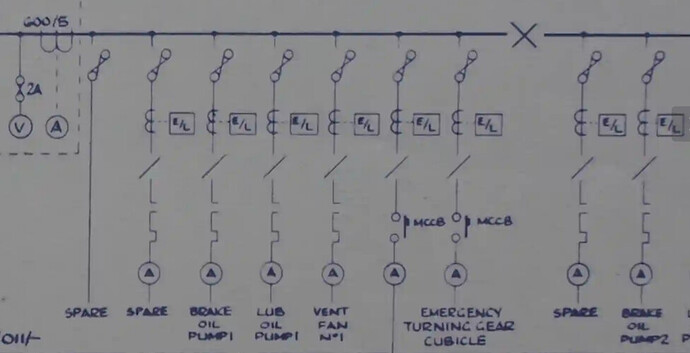

Well… that is a lot of kit!

A simple answer is difficult as it would surely over-simplify, so this is more of a tactical response, along the lines of “how would I analyse this” if I had just moved into your house. Also, the answer very much depends on your starting point in terms of physics, electronics, and computing… and how happy you are doing what most people get an electrician for…

First thing is to do your homework concerning what the kit is already doing in terms of power etc, and what data can be acquired. Quite a lot of inverters have an RS485/Modbus interface which can give access to useful data. A simple dongle plugged into an EmonPi can translate that into a form which the EmonPi can record for you to analyse with EmonCMS.

EmonPi is a good bit of kit to get, to get working, and to learn with. The usual approach (which I started with) is to use “current transformers” (aka CT) but I now also have a SDM120 (there is a 3 phase version) for my heat pump consumption. It is a module as fits in consumer units so if you have a spare slot, or an existing “dumb” energy meter module, that is an easy replace.

Draw a diagram, working out what the flows of electricity are, and where you need to measure.

Depending on your heat pump, you may be able to get “good enough” data on heat output without needing to fit the OEM HP monitor kit. For example, I have a Daikin EDLA and use the ESPAltherma. I calculate an estimate of heat output based on flow rate and temp increase and get CoP values which are generally close to the data book values for the EDLA.

Take your time in putting monitoring in place; having planned ahead, take one bite as a learning experience. For example, an EmonPi with 2 CT;s. Get happy with that then put an SDM120/360 in with an RS485 dongle on the EmonPi. Direct query of inverters by RS485 is a bit more hairy… However, it you look into the Home Automation system, maybe that will be more accessible. Lots of people have written adapters.

I’ve been singularly unimpressed by most products in terms of access to data. Each manufacturer has their own app and clound-based system but generally with little scope for integration.

hth a bit…