A clean power supply is actually very hard to achieve, even without the noise from running it off of the PC’s 5V supply for USB. Using USB power from a PC is fine for many things, but it will be noisy. Even with a clean supply, using an esp8266 will make it really unsuitable for anything that needs a stable-low-noise supply. While I suspect the esp8266 is especially bad, all MCUs generate a fair amount of noise.

Having said that, it depends on what you need/want/can afford. Even a system with some amount of noise and inaccuracy can provide valuable information with which to make decisions. My Brueltech ECM1240 used to say that my dryer was drawing 7W all the time. I wasn’t sure if I should believe it. But, the dryer was one of the first digital ones and has a power supply that is always on. I was going to put a hard switch on it, and even bought one, but never got around to installing it. Now I have the dryer on an Iotawatt and it says it is drawing nothing (when off). Which one is right? I am not really sure. But I have done other tests that lead me to believe the Iotawatt is. I have one CT on a circuit where I can control exactly what is on. It shows 0W when nothing is on and the correct value for known loads (small and larger)

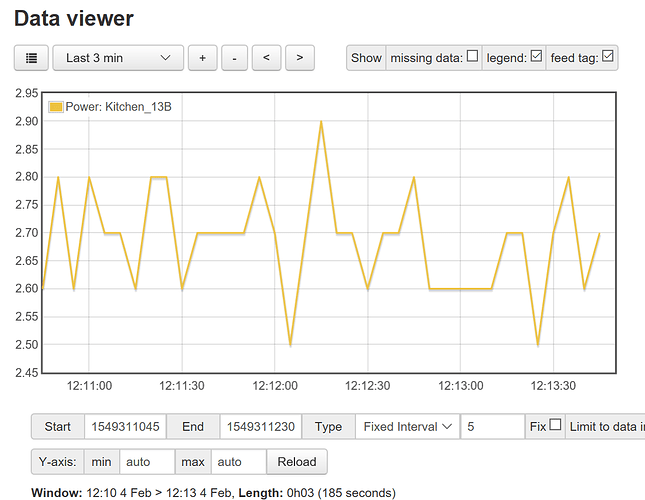

Here is the loads from an answering machine and computer in standby

Here is the power that my range draws for the clock:

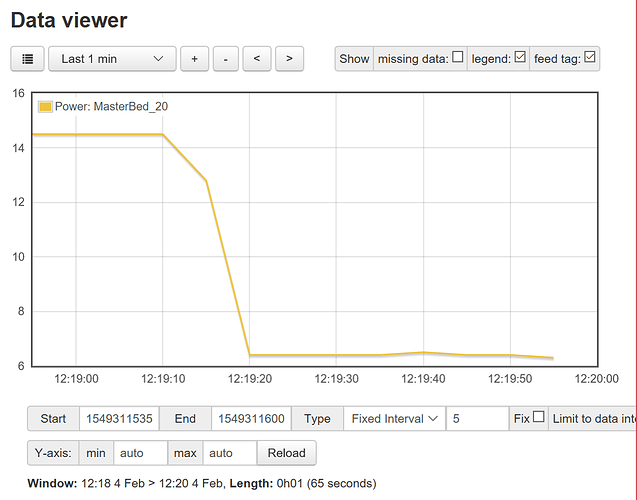

Here is the bedroom with only the closet light and smoke detectors and other always on load and the transition when I turned the light out:

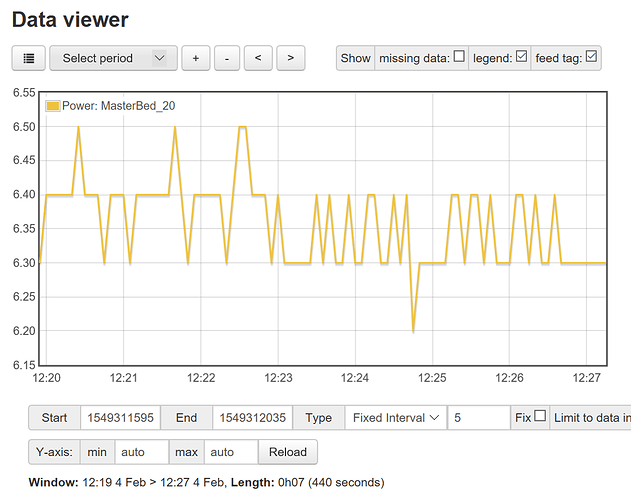

and here it is with just 6 Nest smoke detectors, the control for a sleep number bed, and Big Ben Moon Beam clock. Since it has a 50A CT on the circuit, the load is at 0.1% of full scale. With a consistent load the results are very consistent.

Here is the 7 min view:

Here is the basement shop:

Looks like Alexa woke up and checked for updates

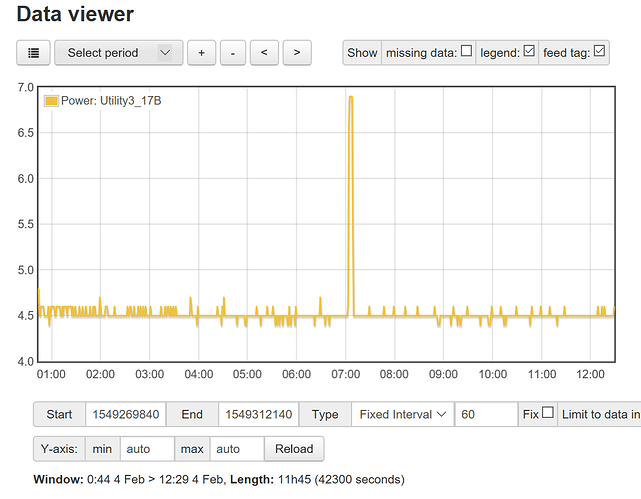

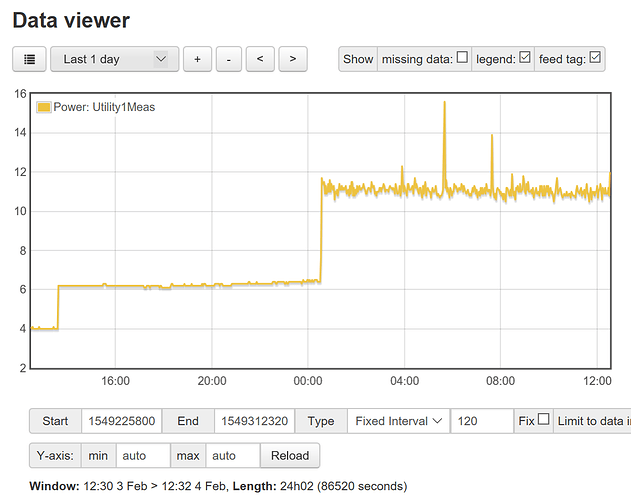

Now here is my utility room with the new circuit I added:

The first jump was when I moved some additional esp8266 based stuff over to the new circuit. The second was when I moved my PC that is running all my home automation stuff (NodeRed, MQTT, InfluxDB, Grafana). It stays on always, but turns off the display after 2min to save energy. You can see the signal got a lot more noisy when I added it. That is because it is always changing how much power it is using based on what it is doing, but is still averaging at about 5W, which is little more than RPi, but way more capable performance wise.

Anyway, my point is that it is certainly possible to get reasonably accurate results at low power levels, but it is not easy.