My AE080BXYDEG/EU is about 2 x oversized (installer’s conservative MCS calcs, as usual), so cycles every 30min despite a 50 litre buffer tank in the CH circuit.

The ASHP compressor is nominally fixed speed but the manual hints that the one way to force a reduced speed (hence power requirement, hence cycling) is to enable Quiet mode.

Has anybody tried this, and if so does it affect ASHP power (i.e. increase CoP)?

Thanks!

I have a similar situation with my Daikin, so it’ll be interesting to hear what you find.

I tried quiet mode yesterday and all it seemed to do is restrict the heat pump to the lowest output, which is pretty much what had been happening anyway, 1100w in the case of my 11kw Daikin.

Hopefully you have more luck.

Mitsubishi also has a quiet mode, which I tried for a while. Like Sam says, all it did was reduce the output when it was already running on minimum anyway. May have a bigger impact in deep winter.

I tried quiet mode on my Daikin on Friday as the Daikin employee said it would reduce electricity input and heat produced by 50%.

I can’t see it did anything at all.

I am not sure how it can, if it is heating the water to a set flow temperature and it can do it for less electricity why wouldn’t it already be doing it?

Maybe it cuts the noise when it’s really cold and working hard?

Thanks Sam/Tim.

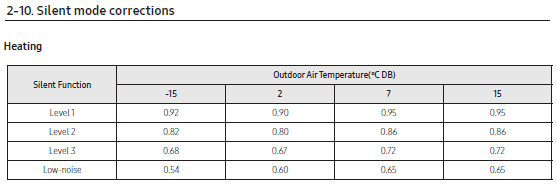

I’ve been sent this table of “capacity corrections” by my contact at Samsung Support for my model:

The bottom row suggests that the effect is indeed larger in winter, though not a lot.

I’ll give Quiet a try on a cold day, comparing before and after on power consumption and cycle time.

Hi i jave a 16kw Samsung that i feel is also oversized so it often runs at a minimum speed and still overshoots flow temp.

It would be interesting to lnow what flow you have around your circuit

I improved my flow by altering some of the ground floor circuits onto a new feed and this upped my flow by 5 lpm and it improved the running and i also made sure all radiators were outputting there max by using a thermal camera to check the surface temp of each rad to ensure i was getti g max output.

I am going to increase size of two of my rads to see if this would help

I think i could have got away with a 12kw but im not sure that isnt the same u it as the 16 so rhe min speed and output may well be the same.

Hi John and a warm welcome to the community ![]() .

.

I’ve learned a lot since my original post:

- My ASHP compressor actually spends most of its time at minimum speed (~50%) anyway, because my LWT is at/near the weather compensation setpoint. So Quiet Mode would only make a difference when starting from cold (e.g. night time defrost cycles).

- You don’t get something for nothing, and hobbling the compressor by enabling Quiet simply takes it longer to do anything (like heat DHW) - 15 mins @ 3kW costs the same as 30 mins @ 1.5kW.

- If bigger rads allow you to increase your CoP (by reducing LWT a bit) then they are often a cost-effective investment. I did just my living room and that gave me a 2 year payback on the installed cost of doubling the rad area.

- For an 8kW ASHP my primary circulation is ~21 l/min which gives an ASHP deltaT of ~3degC.

- I recently “calibrated” my living room and confirmed that the overall MCS-based OHTCs were reasonably accurate. (The installer’s heat loss calcs included an unrealistic ventilation factor per MCS method, so I too have an oversized ASHP.) This calibration included back-calculating the effective room (m.Cp) so I can estimate the additional sensible heat requirement when starting from cold.

Hi Sarah

I have just replied to someone else about a similar situation

He has troule with cycling to often.

If you have hydraulic separation then if your secondary circuit isnt as high flow its always going to be a problem unless you can manage to increase the flow to match by adding an extra rad or some other emitter

I removed the separation i had as a trual and it does work better but i have also added an extra flow and return so 3 of my downstairs rads are no longer on the original loop. This was quite easy as the pupe ran under the kitchen cupboards back to where the heat pump comes through the wall

Even though my house is 220 years old and solid stone it does keep the heat well so i can use my external room stat to switch off at 20.2 and come back on at 19.8 so my house works as the thermal store. I only need to do this when its above 7 outside as below that i have enough emitters to run at about 32 flow temp so ticks along quite nicely at its minimum speed which absorbs around 700 watts

I am told by my good lady that the tinkering must stop soon as its driving her mad. Its only been going on for three years but i think im about done know

Regards

John

Hi John.

Between you and me (and your good lady, it seems) I suspect that there are a fair few in this community who have forgotten the “don’t let perfection be the enemy of the good” adage, aka if it ain’t broke, don’t fix it.

In the meantime, I must just finish this spreadsheet… ![]()

Sarah

Hi Sarah,

Can we read number of cycles on Samsung MIM-E03EN, I went thru manual and could it find it?

Not without some sort of monitoring kit, Michal.

I wonder why you are looking for this data? For any given ASHP heat output (which you can calculate from m.Cp.dt on circulating water), cycle frequency depends on the thermal inertia of your circulating water and the hysteresis of the LWT controller (if weather compensation is enabled) or on the thermal inertia of your house and the hysteresis of your roomstat (if it isn’t).

You can estimate these thermal inertia values fairly easily, and the MIM-E03EN hysteresis in weather comp mode is “about 2K” (Samsung Tech Helpline), so if you know your roomstat hysteresis you can predict your cycle times both on WC and roomstat control.

Or you can simply watch the remote display (Settings/Operation Status) for an hour or two one day… ![]()

I know that Panasonic heat pumps have this indication also my gas heater have number of starts and running hours. My house is around 180m2 floor heating +50l tank, so I`m not expecting cycling but I think it would be good parameter to look at. Thanks for confirmation.

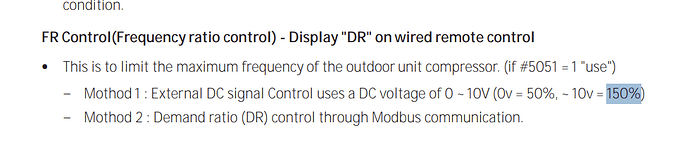

I know this is an old thread @SarahH but have you played with the frequecny control stuff.

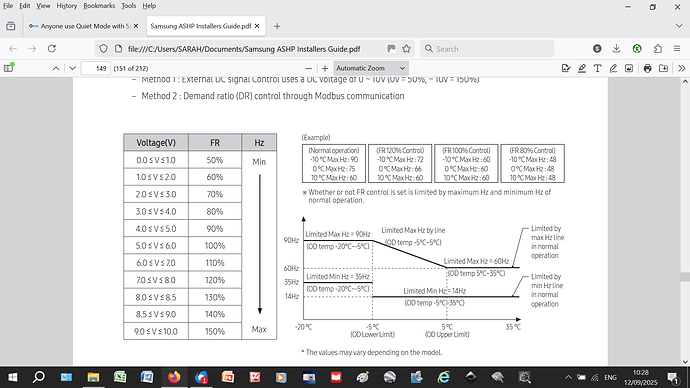

0-10v input to the MIM board can control the power from 50-150% (not sure how they get 150%)

If you turn the setting on and don’t connect anything you get 50% throttling out the box

Hi @mrsimonbennett,

Reading back over this thread, I can see that we were rather conflating two “frequencies” - compressor inverter frequency (which Quiet mode sets) and heat pump cycling frequency. I assume that you are referring to the former?

I confess that I am somewhat perplexed by your words:

Can you clarify these words, please? Which “power” are you saying that you can control? (compressor motor current? inverter frequency? noise level?) And what is the reference value to the “50-150%”? (i.e. what value is 100%, and what variable are you referring to?) And what do you mean by “don’t connect anything”?

Sorry if this sounds like I’m being obstructive (certainly not my intention) - it’s just that I’ve been spending a lot of time this summer trying to learn more about the MIM serial data traffic (what it reports via F1/F2, and what SNET-Pro2 tells it to do), and your query suggests that I have missed a major trick. (I had assumed that we could only update FSV values remotely, but you make it sound like there’s a way of forcing the MIM to revise its settings if you put volts into the right place - your “0-10v input” reference).

Thanks for any assistance…

Yeah no worries, I have sorta put the two to mean the same, less compressor power will reduce cycling too esp with DHW

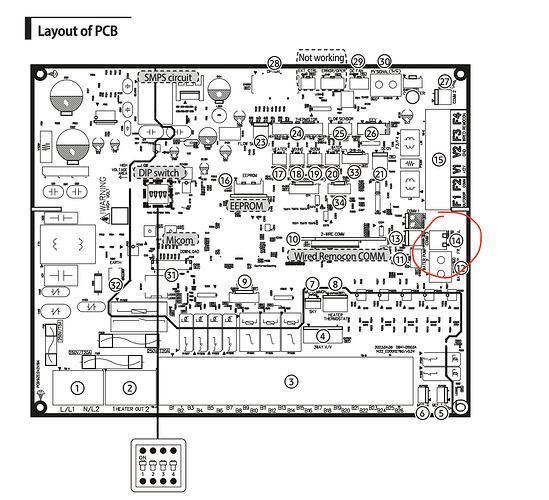

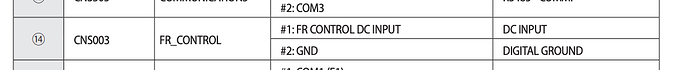

See some screenshots from the MIM installers and user guides.

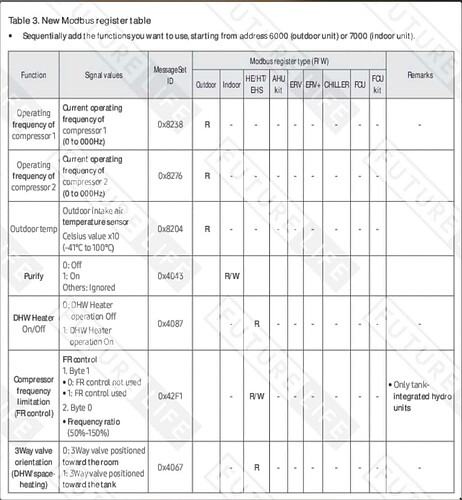

At first, I was trying to get MODBUS to accept this, having poked around at the registers for too long I found another document online that says this only works if you have the integrated hydro unit that I don’t.

So anyway I turned #5051 to use. And the compressor frequency is capped at 40Hz (or thereabout). I have found this to be a bit lower than the quiet mode, which limits output to about 60%.

By simply turning #5051 to use, and not connecting a wire, you are telling the Unit there is a 0V input, and that will be down at 50% max power. Ideally by setting up some controller to send variable power pins you could go from 50 to 100%. (not sure how you can get 150% unless this is some cheat code :D)

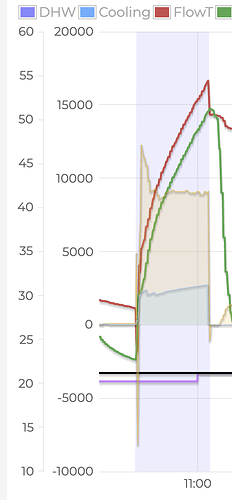

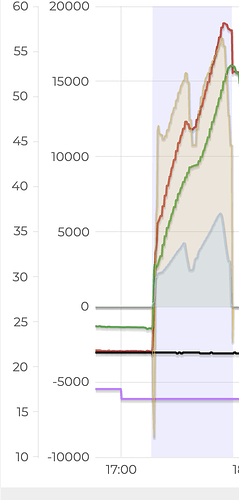

Screenshot with #5051 set to use and 0v

Screenshot of #5051 not used and be turning on quite mode on and off. You can see the power peaked at 18kw. COP was pretty terrible

Interesting stuff, @mrsimonbennett, I’d never investigated #5051 before. There’s a bit more info in the Installer’s Manual:

Out of interest, the normal inverter frequency range on my AE080BXYDEG (with FR set to Off) appears to be 20-60Hz, irrespective of ambient temperature. (That’s based on dozens of hour’s SNET-Pro2 output over last winter.) So I find the above diagram rather puzzling, as it suggests that the allowable frequency range varies with ambient temperature.

My data suggest that the compressor BEP lies around 50Hz (i.e. synchronous), and falls off somewhat at higher or lower frequencies. But that conclusion is far from definitive - there’s so much oil circulating with the R32 that the mixture physical properties needed to calculate polytropic efficiency are impossible to estimate without knowing the OCR (which Samsung keep secret, of course).

I was trying to find that diagram to add to my post, but yes I have looked at it many times and been confused by what ie means, like if you set it to FR100% you set the max hz to 60hz no mater teh temp. Does the diagram mean, it will just protect the unit when its cold or does it mean something else?

Like the 120% example shows the max been less than normal operation.

Samsung have an amazing art at making the simple complex

…plus they seem to have employed a school-leaver to translate the manual from Korean…

Yes, that diagram shows that you set the max frequency, but it will be limited by other conditions too (temperature). 120 % max is lower than normal operation because it’s not 120 % of original max value for specific temperature, it’s just 120 % of 60 Hz

Anyway, wrt to this topic, I did some experiments and went sort of the opposite way. From my measurements for my system (8kW r290, 750l buffer tank, FCU+UFH) when I try to stretch the “on” period by forcing it to run with lower power, the COP drops to mediocre values. I even noticed significant drop in COP when it tries to slowly come to requested water temperature. As a result, I’m no longer trying to prevent cycling no matter the cost. For low heat demand weather I set temperature aprox +5C higher than what I actually want, let it climb with “full” power (quiet mode on) and then turn it off (using Home Assistant).

Dear @mrsimonbennett @SarahH ,

I must say I love your findings, I’ve ditched the samsung manual and went toward the reverse engineering side. But I think I misread the part you’ve pinned in this post, concerning 5051 and FR control. I hadn’t checked the 42F1 register just yet.

I do have a question though. I added support for home assistant based configuration. However, when I switch the FR control using 0x42F1 set to 0x0132 (enabled with 50% max). the FSV 5051 0x40A7 register remains set to 0, as if setting enabled to the 42F1 had no impact. should I run some test to see the effect, or had you already went that path?

Cheers,