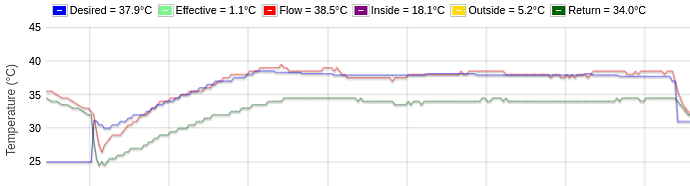

Yes, I’ve seen this too. My solution is to limit the target flow temp to the return temp + 5 degrees (or whatever the optimal dT is for your system). This allows the heat pump to raise the temperature slowly without overshooting, and (maybe) reaching a steady state.

^ 6:30 until 10:30 am today. Compressor power was between 26% and 38% for this cycle, which is about as low as this unit* can go. [*EcoDan 11.2 kW]

This does require monitoring the heat pump very closely, and adjusting the flow temp every other minute. Here are some related threads that might provide interesting background: