I was wondering whether anyone else with a heat meter monitored heat pump has a Mixergy cylinder attached?

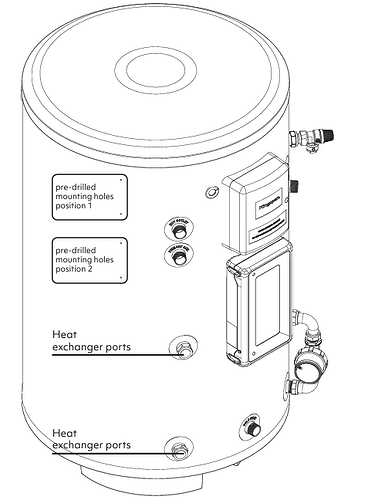

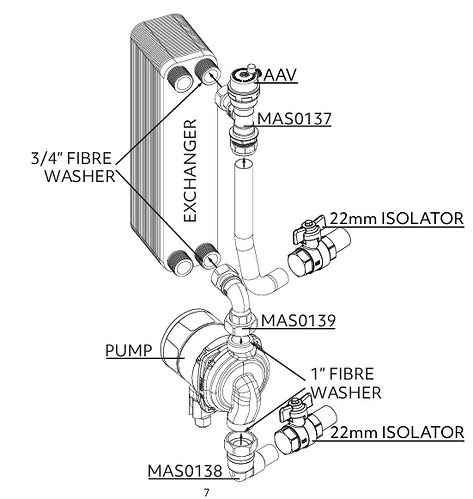

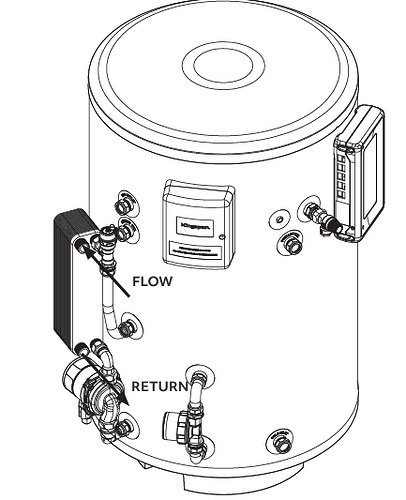

I’ve got a 250L direct version with both the heat pump plate kit and also the PV divert module so I can run the myenergi Eddi against it. So no internal coil, just an external plate heat exchange.

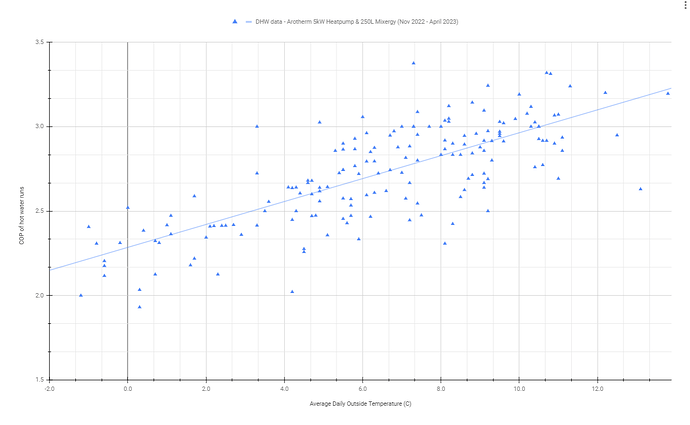

It’s running alongside my Vaillant Arotherm 5kW heat pump.

https://emoncms.org/energystatsuk

Reason I ask if anyone else has one is that there’s a little more to tinker with control wise.

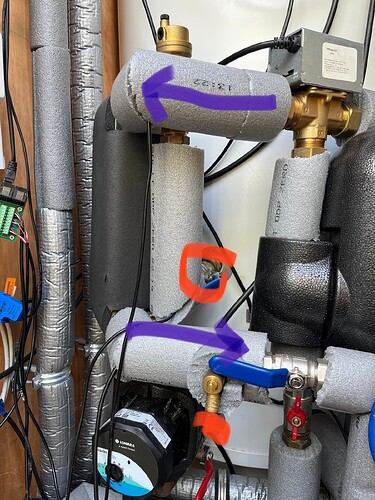

ie, there’s the added complication of the pump speed on the clyinder side, as well as the whole Mixergy % full unique selling point.

Plus, you have to trick the heat pump controller into knowing about the Mixergy on the heat pump controls (in conjunction with the Mixergy heat pump little control box)

My cylinder has a Lowara ecocirc M 15-6/130 N pump. Not sure if everyone has this pump?

Back and forth with Mixergy and their standard answer is “stick it on fixed speed 3”.

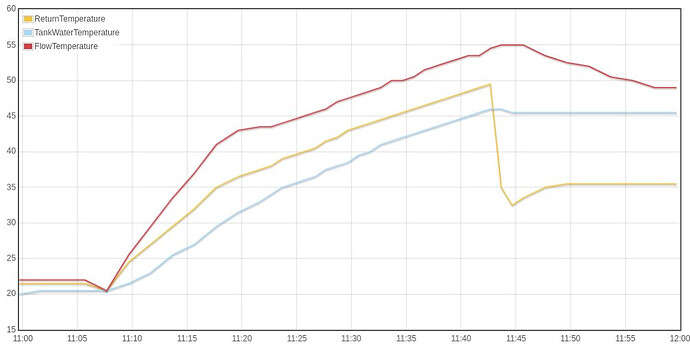

I’ve also been tinkering with the pump speed on the Vaillant side.

Should the flow rate on vaillant side match the cylinder side?

No one, including Mixergy or Lowara can tell me the flow rate at 1,2 or 3 pump speeds.

I wish i’d had a flow rate meter put in on that side.

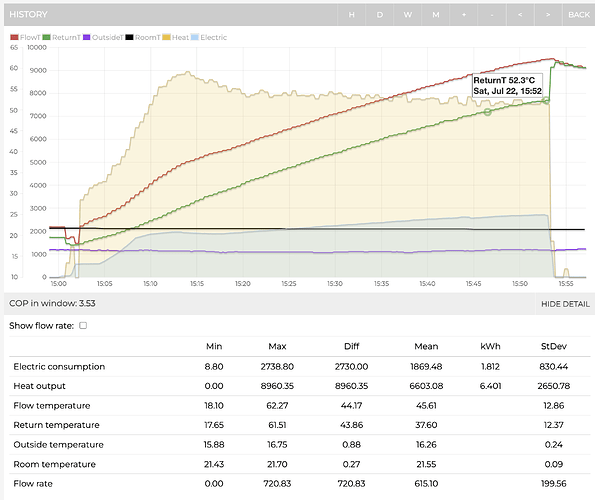

I’ll be honest, even after a full winter i’m not sure if i’m getting the best COP out of it.

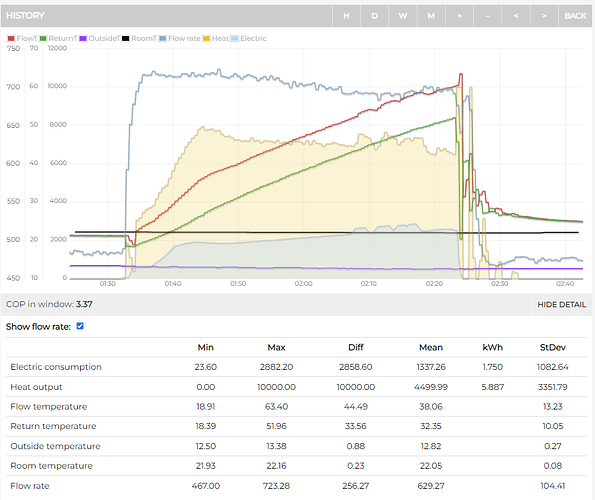

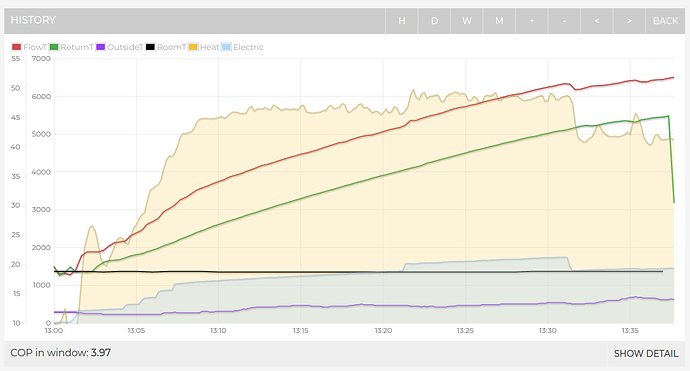

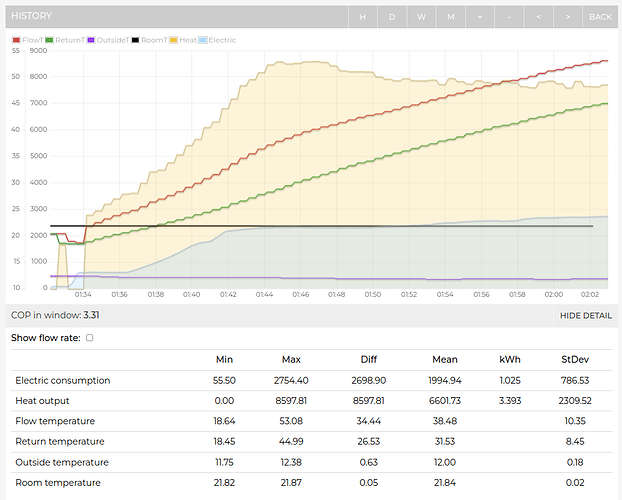

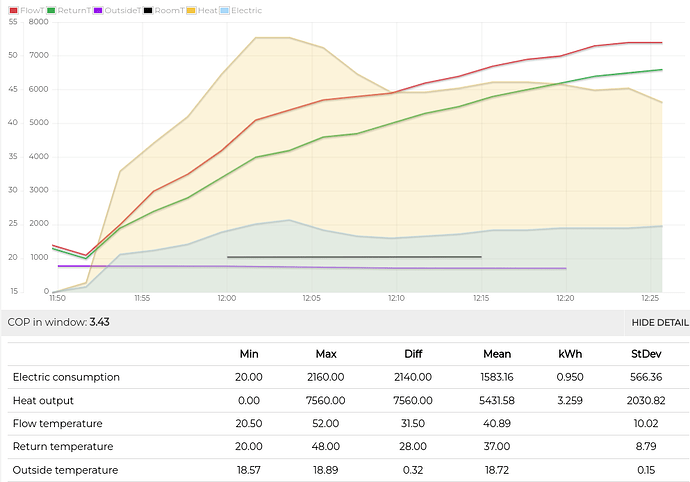

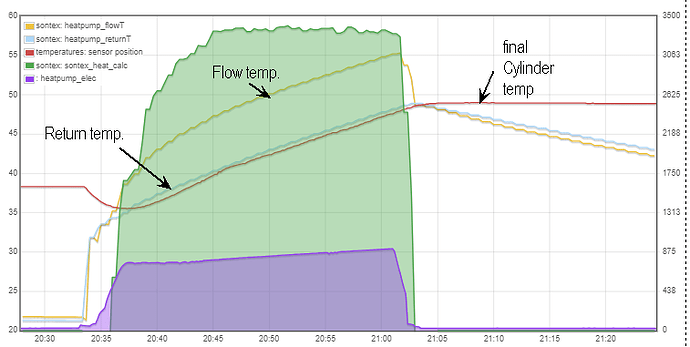

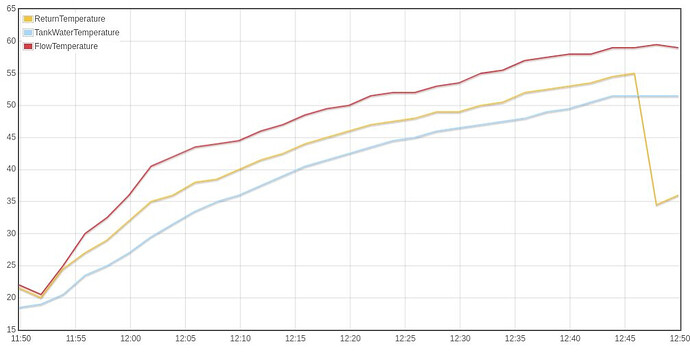

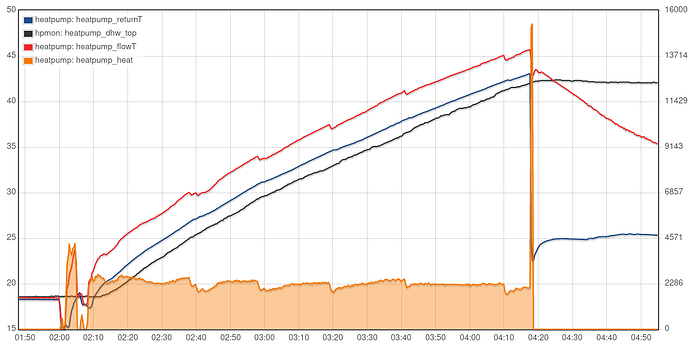

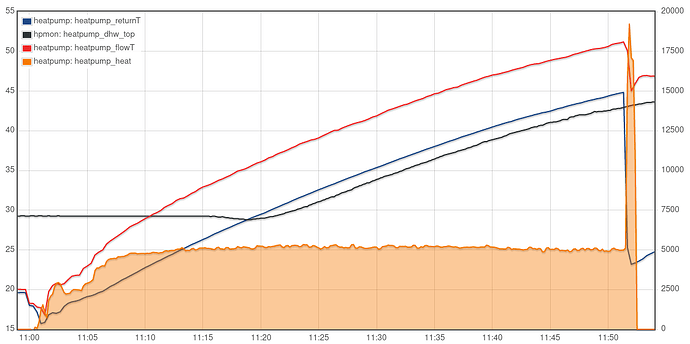

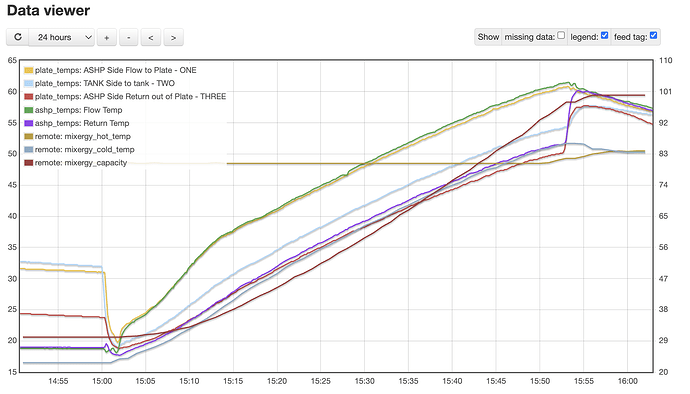

Here is this mornings run (this is Auto flow rate on the Vaillant side, pump speed 3 on the Mixergy)

Which was around 45% to 100% full at target 50C.

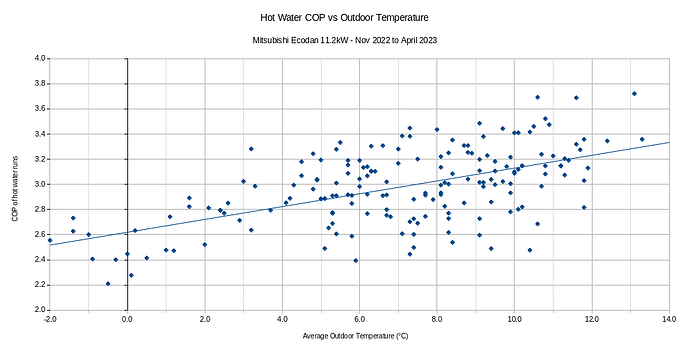

I need to do more investigation, but anecdotally it does seem its better at long hot water runs than short top ups… but I think that is true for most heat pumps?

if you have a Mixergy, please let us know how you’re getting on with it.

Or whether you’ve got any tips/tricks how to get the best out of it alongside a heat pump. ![]()