Hello all. I recently setup an EMonPi2 to monitor the power usage at my shop and I’m not certain that I completely understand the data I am seeing nor am I completely certain that I have everything installed correctly. actually I’m pretty certain that I have a couple clamps on backwards.

This question is turning out to be a little longer winded than I had intended, but I want to make sure I give enough context.

We have a 200amp 3 phase 208v service, and I run a couple CNC machines for my business. I am trying to figure out if I have enough capacity to put another machine in the building on the current service, and I am trying to figure out how much each machine costs to run.

I have 3, 200 amp clamps around the main feeds to my panel and individual clamps sized according to the breaker rating on each line of the circuits for my machines.

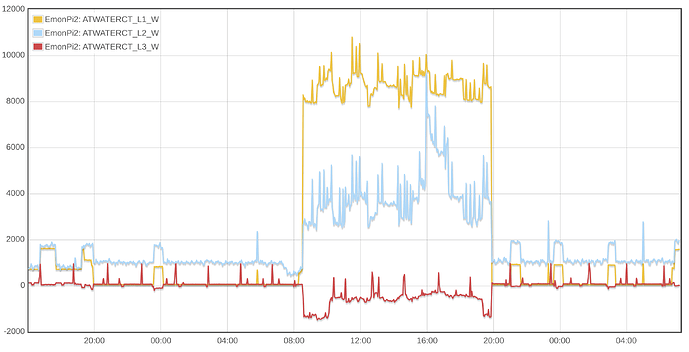

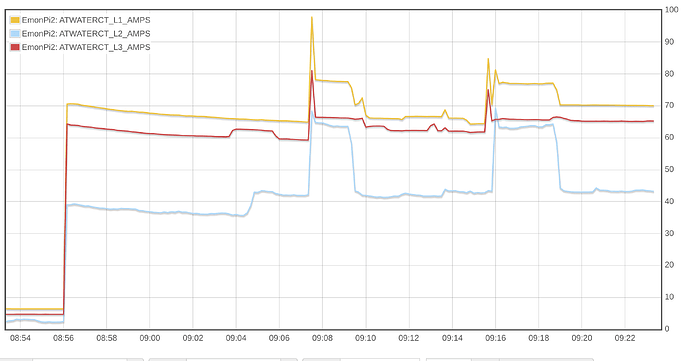

Yesterday I ran a normal day’s production, and got the follow data for the main service power:

I assumed when I initially started getting data that the L2 power was higher than the L1/L3 power due to some unbalanced load in the shop. at the time (20:00 on the graph for example) the only things running in the shop was the lighting, office fridge/computers/etc and main office airconditioner. The AC unit has a 50 amp 3 phase circuit, which I plan on monitoring in the near future. I figured 1kw on a single phase wasn’t too much imbalance.

What I didn’t notice and what becomes even more apparent at 8:00 the next day is that L3 was recording both positive and negative values. At 8:00 the L3 power goes negative, and the power imbalance between L1/L2 becomes about double.

All of this is very confusing to me. I’m not certain why a current clamp can read positive AND negative values, nor am I certain that I can trust so much power imbalance to be accurate.

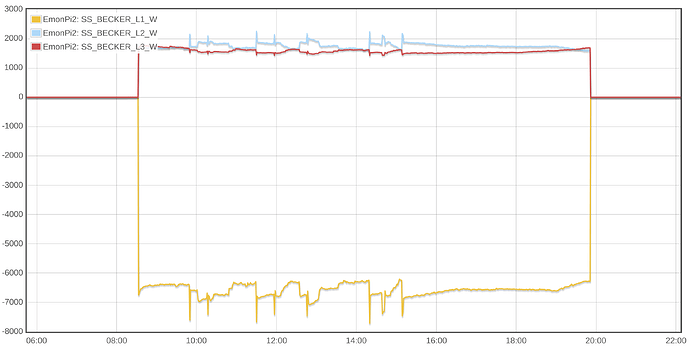

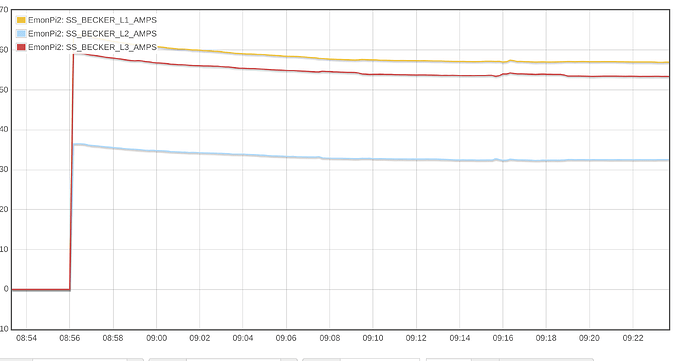

If I drill into the individual components of my CNC machine(s) I get similar but still confusing information.

The largest power consumer of the machine is the Vacuum pump. It’s a Becker 17.7HP VLTF pump. The manufacturer says that at 3PH/208V it should need 55amps. I have it on a 100amp breaker, and am monitoring it with 100amp rated clamps.

The L1 clamp in this image is obviously installed backwards (though I believe I oriented them all the same direction when I installed them) and I believe I have the L1/L2/L3 mis-labeled. (I need to double check, but I think I have L1/L3 labels backwards)

What is concerning to me is the magnitude of difference in the power consumption on the phases. Why would I see one phase at 6500W and the other two around 1800w?

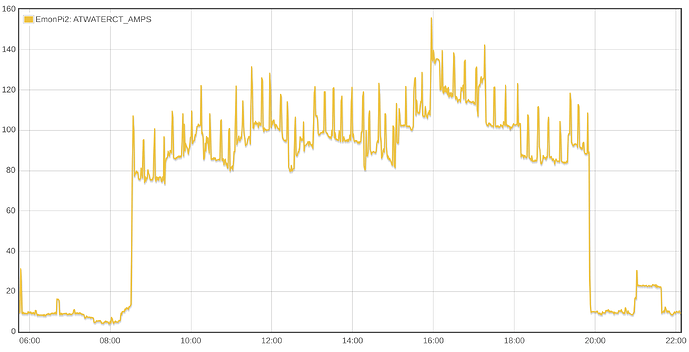

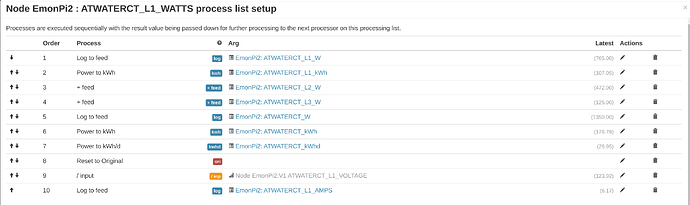

Since I ultimately was interested in if i had enough capacity to add another machine, I added a feed to calculate consumed amps for the whole shop based on the main L1/L2/L3 power inputs

which gives me this graph:

Since some of the underlying amp feed calculations are negative, this graph is a little lower overall than I think it potentially could be. but I’m also not certain that this is the proper way to do the calculation.

I guess ultimately, I have two questions

-

Are the power measurements that I am seeing accurate and if so are they concerning?

-

Am I calculating the amp-draw of my equipment/shop properly?