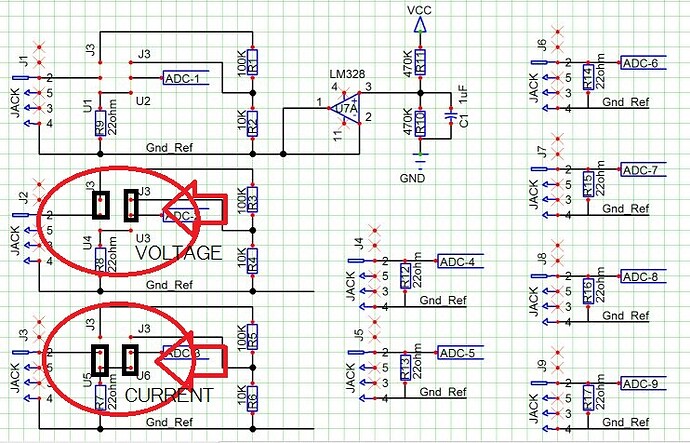

Schematic is my full compliment of 9 ADC inputs, 3 are either/or voltage/current

the other 6 are current only, all share one OP-AMP for reference

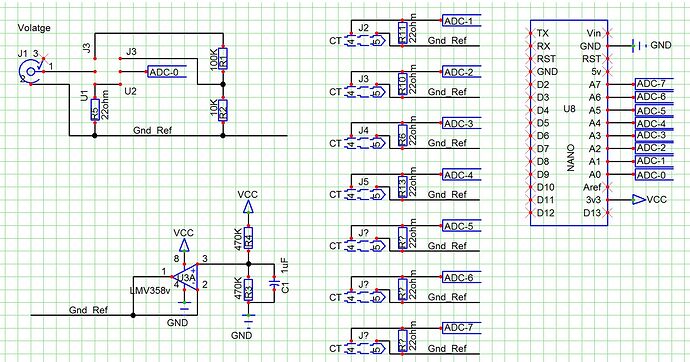

My application is for a 3-phase panel

Measure all 3 mains voltages and the 3 mains current

In addition, measure one 3 phase motor.

I am thinking, 9 inputs, 6 with CT’s and 3 for voltage

Using the simple Current sensing is easy, just get the correct range CT’s

Voltage and 3-phase add the twist.

Since detecting a loss of a leg of power is part of my design goals, I want to measure all 3 voltages.

The mains voltage in this particular instance is 480 3-phase. (I’m in the US) It appears that it would be best to measure line voltage (phase to neutral), not phase to phase voltage.

When I have boards made, I get 10 at a time from the board house.

I am thinking that with a few extra pads and some jumpers, I can make a 9 channel all current sensing board. See the first 3 channels.

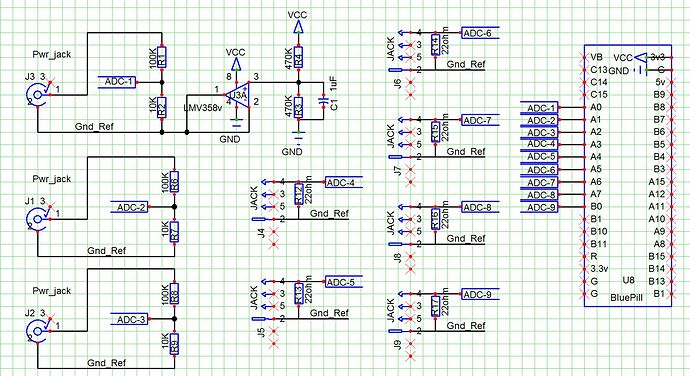

The plan is to use a BluePill STM-32 based board on the board.

Also, if I have 10 boards, I can see that I will want to populate a second board with all current sensors and it’s own BluePill

One question is how best to have all of these talk to each other. Probably use one ESP8266 as the one that ties them all together and offers the WiFi out.

I will be using the Arduino IDE for these boards.

One of the questions that keeps nagging in my head is to have a separate voltage only board and use the ZMPT101B transformers so as to have one board with the high voltages be separate from the current sensing board.