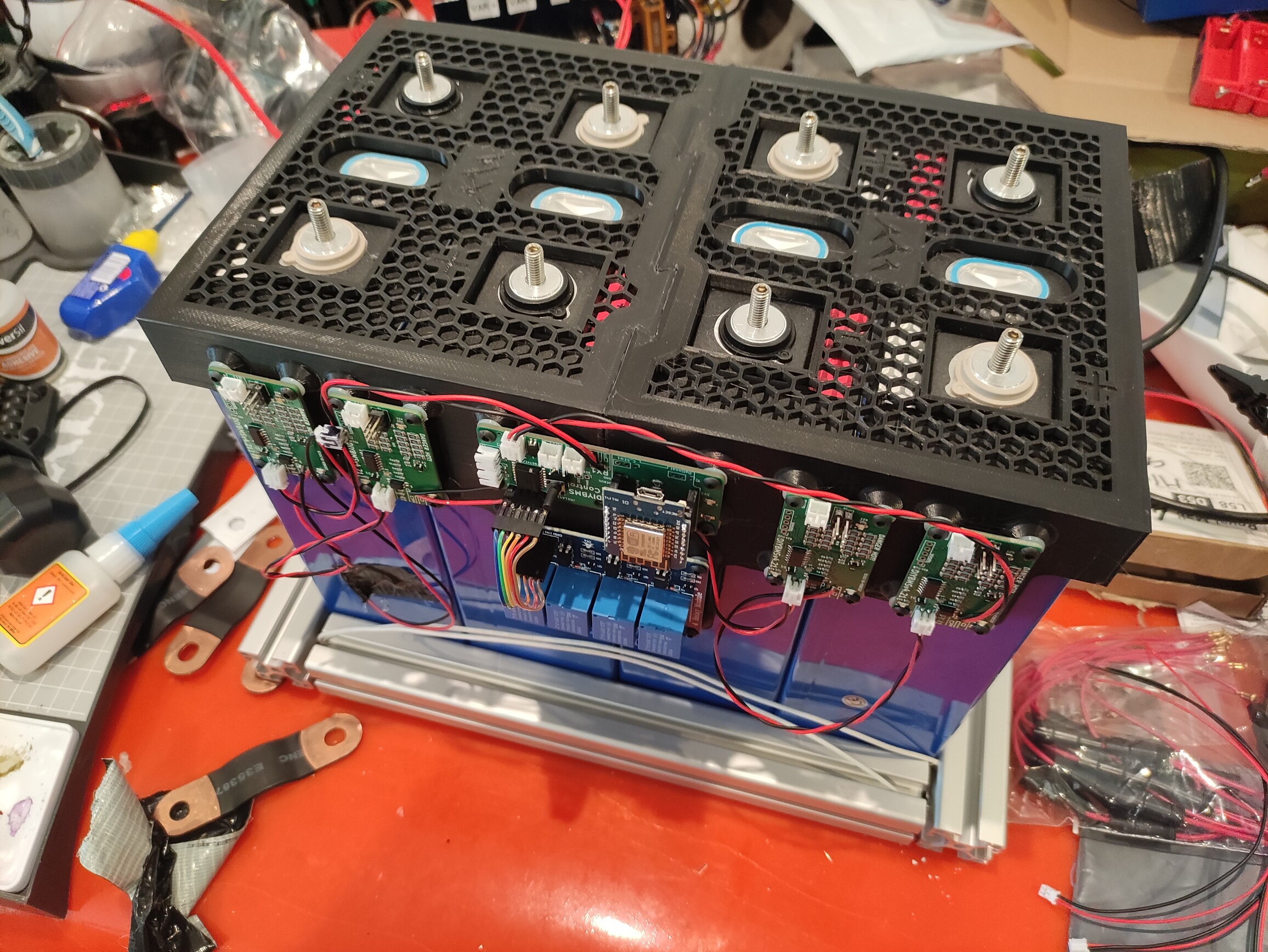

Looking good!

For the compression…

Yes supposingly you are able to increase the cycle life.

That’s just one added benefit.

I have over 80 cells, 32* 280 52x 152Ah that I started with and like you are, naïve.

I didn’t clamp the 152’s and after a few months of usage with solar and low capacity setup (S16, 51.2v) almost all the 152 are (slightly) bloated.

Never over charged,

Never over discharged,

Never beyond 0.1C rate.

The 152Ah seems to be little more prone to bloating, too much sheets in the housing, as the same housing is also used for 120Ah.

A bit like the 310Ah now who have the same size as 272/280.

Fact stays…

They bloated.

Only because I didn’t clamp the wide sides.

It doesn’t have to be a crazy tight fit.

10mm plywood is strong enough.

It just needs some additional help keeping the thin aluminium walls in place.

Official (Eve) build has aluminium casing that is laser welded around the cells while being compressed.

And laser welded busbars.

https://youtu.be/xdl5a2iyPYU

Please do watch this video to understand how the cells are intended to be used.

We are playing with half fabrication product, that needs further assembly as shown in the video.

As most of us don’t have a laser welding system, we use alterative.

Like drilling holes and tapping threads. (Done by your seller to make it more accessible for wider public, NOT the factory!!!) (except CALB)

That’s just one part of the process.

Anything we do different/ less is outside the specifications of the factory and will have negative impact on the lifecycle.

Did it hurt? The bloating?

After a year of usage, I did capacity test of all cells, 142-151Ah

Daily cycles.

Most ended around 145-148

So yes, it hurt, a bit.

Supposed is 30% rest capacity after 10 years.

With my speed of decay…

4% in a year…

You can do the math.

They are now clamped.

You can compress the bloating a bit, and tightening it more over time as the pressure will reduce some in a month.

Once released from clamping, the bloated quickly back to “original” shape.

I re-tighten not to de-bloat the cells, but to keep even tention on the sides.

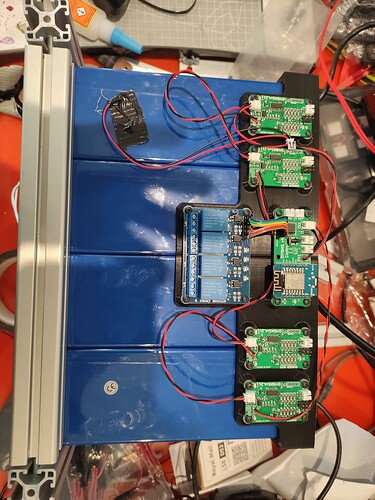

6 * 1/4 inch threaded rods and little over hand tight with pipe wrench.

That’s all it takes.

Just don’t complain after a year or so when you see the cells bloating.

You now know the fix to prevent further damage.