Thanks John that makes things much clearer. So this is an efficiency issue rather than a maintenance problem?

Hi David,

Mine was installed in February 2024 and at least one other in January 2024.

We have experienced these conditions before without this behaviour.

Mine also does it when it is warm.

It only seems to be happening to 8kW models even though they are physically the same as 4kW and 6kW models.

Maybe something in the different software? So fixable with software?

It’s an efficiency issue if it only happens rarely, who knows how often it has to happen to become a fault?

Presumably Daikin tested these things extensively before they released them to the market?

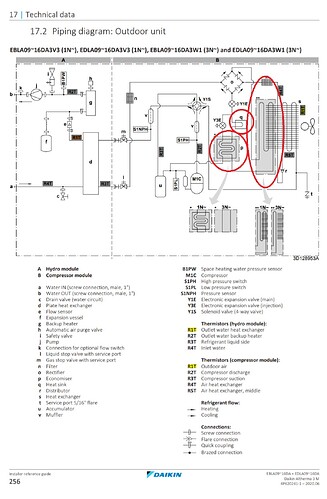

The three parts circled in red are interesting for me. Can somebody take pictures of them and publish here?

Hi John,

This may be relevant.

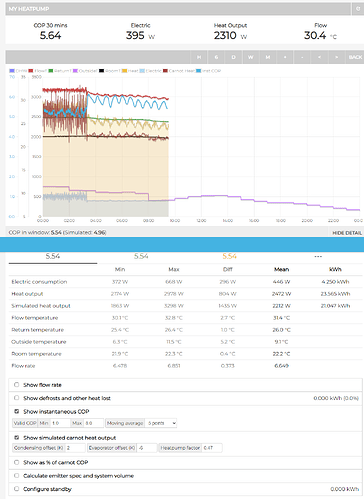

I always have trouble controlling my flow temperature. It is set at a fixed lwt of 31c, but it started the day at 32c and is now 30c. The Onecta app and the MMI show flow temperature is 30c even though it is set at 31c.

What I see is a decay flow temperature and efficiency. Possibly prompted by the fall in outside temperature?

Maybe it is `leaking’ liquid refrigerant into the compressor all of the time? Slowly cooling the flow and losing efficiency?

It’s definitely a production issue. What I see is three Daikin monoblocks with the same issue. The system should be connected to parameters monitoring service software… What I see is you have 2 EEV - one for normal operation, one for EVI… They should be monitored when problem occur. Also it’s possible EVI controller to make an error and to switch to EVI opperation when it’s not the most efficient one. After some time new setting is given and the EVI is switched off. You definitely need qualified installer to monitor the work of the machine when the problem occur.

I think the problem is there most/all of the time, just occasionally much worse.

@johncantor commented on the erratic flow temperature and electricity use, the hunting that we see on all of these models.

Piecing together what I have learnt from comments so far, I suspect the refrigerant is not fully controlled and there is usually small amounts of liquid refrigerant getting into the compressor.

I think this results in the `wildly’ fluctuating flow temperature and electricity consumption.

Based on my observations I think it has an appreciable affect on efficiency.

At times when the flow temperature and electricity consumption are stable the efficiency is relatively much better…

For me at this stage, my conclusion is that it is a design deficiency.

Oh dear.

At the risk of sounding stupid (as usual) did you see this happening before or only after you had the firmware updated on the outdoor unit (for the overshoot 4°c issue).

Could it be a firmware issue and we need another manual update of the outdoor unit (to fix the logic).

Not great that it would need an engineer visit but better than the alternative.

You have to contact local Daikin supplier. I will try to contact one of the Daikin suppliers here in Bulgaria - my friend from university years. Let`s see what we will learn.

Hi Zak,

Yes, I had the firmware update in May 2024 and first noticed the extreme issue on 14 September 2024.

That was the first day the heating had any serious use since the firmware update.

I am still not convinced the thing works properly though, it heats my house and hot water and I get good efficiency, but my radiators are too big I think because I sized them to deal with the 9kW, I can’t get to a low enough flow temperature as these heat pumps and the way they operate don’t like it.

And I have never been happy with the hunting, I put it down to low flow temperatures and the heat pump just being unstable. It may be that I now know why, it just can’t control the flow of refrigerant as it should.

Annoyingly, if you have been following, I have had a visit from a Daikin engineer who refused to look at the heat pump and basically ridiculed me in my own home.

He saw nothing wrong and put the issue down to inaccurate data and the most overly fussy heat pump owner he had ever met.

I have had a visit from a Daikin engineer to investigate the problem.

He laughed at me, said I was too fussy, my heat meter is inaccurate, he made me try to explain how heat pump internals work in my own house and ridiculed me when I couldn’t do it, told me off for not looking at him when he was talking to me and basically got a 58 year old man close to tears in his own home.

It was not a nice experience.

He says my heat pump is working properly as it is heating water and that he would see me again when it actually went wrong which he said was inevitable!

This is ridiculous!

На пн, 2.12.2024 г. в 12:17 Matthew Gregory via OpenEnergyMonitor Community <[email protected]> написа:

![]() …I guess he didn’t get a cup of tea then

…I guess he didn’t get a cup of tea then ![]()

I did offer tea or coffee but he didn’t want anything.

It was a Sunday though, and as he explained to me a couple of times, he was just doing it as a favor, I guess he was in a hurry, and getting home whilst still on overtime rates was probably pretty satisfying.

I have been following this reasonably regularly and can say if the “engineer” didn’t leave with a fat lip and open jaw then you are a much more patient man than I.

The fact that another so called “engineer” from Daikin told me that these outdoor units don’t get updates and I should just do it in app , then proceeded to find and install an update to the outdoor unit that can’t be pushed remotely or via the MMI told me all I needed to know.

Unfortunately it seems that a lot of this is likely outsourced and while I get that some customers are just fussy or don’t listen when you have the data and have put together a reasonable case for there being an issue the fact they send out a third party numpty to ignore you shouts volumes about them as a company.

I guess this could also explain the whole why heat geek cylinders are not supported in their documentation and proves they may have known about this for some time (it would take too much heat from the circuit and force the issue to show more regularly).

For most of the time modern ASHPs work great. I think the suction is dry of refrigerant for most of the time, except for a small bit of ‘frothing’ oil returning. The point at which the suction pipe is ‘dry’ should be back in the evaporator, but then occasionally liquid comes into the compressor and heat output drops. The system should immediately close the EEV. However, if it closes too much, it then overshoots and oscillation (open/close) sets up, and it can be quite tricky to stop. However, we want the liqid coming as close to the compressor as possible so the entire evapotrator area is ‘wetted’ . So, if the system is tuned for maximum efficiency, it may well risk coughting and spluttering. Generally, the COPs are excellent

He was not out sourced.

He was a full on Daikin employee.

Well… when I first saw what I thought was liquid coming back to the compressor I worried about lubrication issues… liquid refrigerant might be able to wash off the oil film. However, I am assured that compressor design has moved on, and they are desiged to tollerate it. I still wonder if it might be shortening the life of a compressor… I really dont know.

sorry, not enough room in my brain to get to grips with this. We probably have definitions problem here… not sure what the economiser actally is. Looks like a bridge-rectifier on that Daikin diagram!! I know some (sensibly) fit suction-to-liquid heatexchangers on R290 models to increase the COP a bit.

Your brain is just fine, @johncantor… ![]() , you are quite right as usual. @Ivailo_Stefanov was asking a similar question, I think.

, you are quite right as usual. @Ivailo_Stefanov was asking a similar question, I think.

I now realise that the economiser (Samsung call it an intercooler) takes a slipstream of condensed refrigerant and flash cools it (to close to compressor suction pressure), which 1) subcools the main stream prior to the main EEV, and 2) fully vaporises and superheats the slipstream and thus the whole compressor suction flow once mixed with the main evaporator outflow.

The subcooled EEV feed results in a lower flash % which results in a reduced refrigerant circulation rate, but the superheated compressor suction requires more compressor energy.

There is a subtle trade-off between the extra compressor work (per kg refrigerant) and the reduced kg/h refrigerant, which the heat pump controller optimises by varying the stripstream flow (via its own EEV).

The literature suggests that this optimisation can be worth as much as 20% on CoP if applied correctly, which presumably justifies the extra cost and complexity of the extra hardware.

Sarah

Hi Sarah, I think we need to speak the language here appropriate to the readership, who often speak a language thet I dont understand… one of digital data. I easily get baffled by the words. Anyhow, I had always thought the injecting liquid into the suction pipe was done so a heat pump can reach high temperatures without the compressor discharge getting too hot,… important if you want normal refrigerants to go to say +60C. I never thought it helped COP. R290 of course can go higher, so I would never think injection would help. Some of the higherst COPs are seen on simple ‘no frills’ refrigeration circuits. That said… do Vissmann do anything clever ???

The output dip issue we are looking at is the opposite end of the spectrum… liquid ‘spilling’ over from a flooded evaporator, as opposed to injection where a small amount of liquid is deliberatly ‘metered’ into the suction.