Catching up - apologies, @JustPlaying, for failing to notice your reply, with its questions, before now …

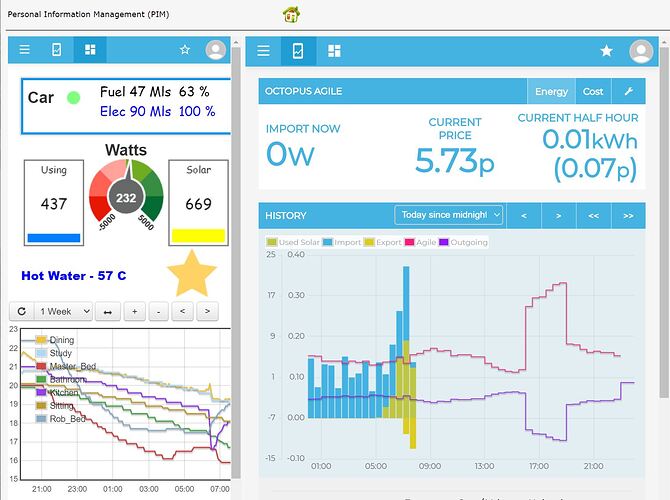

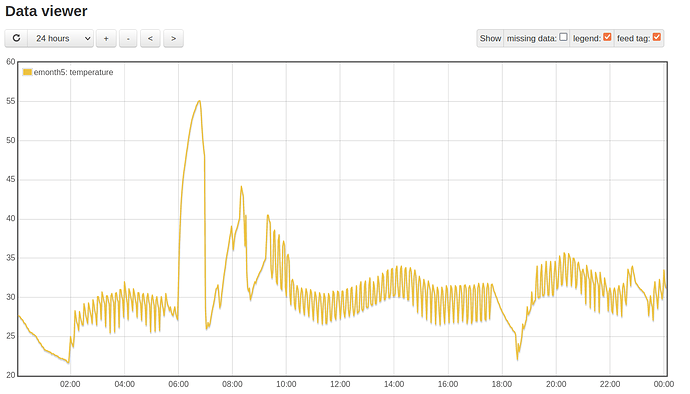

Almost by chance, I strapped my single temperature sensor on the “return” pipe, after the CH and HW returns have merged and about 30cm before it enters the heat-only boiler, and have been observing for a couple of weeks or so. Very instructive. Here is the last 24 hours:

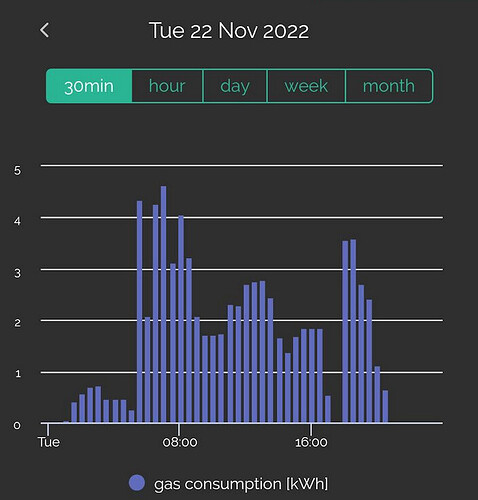

and here, for comparison, is my smart meter’s indication of gas consumption for the same period

(not quite complete - the consumption from 21:00 onwards wasn’t available when I took that screenshot, but it was about 0.9 kWh per half hour). The main features in the emonpi temperature plot are: boiler off up to 2am, then gentle heating till 6am (it was a cold night) before the water heating starts at 6am (the water temperature reported by evohome had fallen from about 53 to around 40 over the course of the day: water heating is limited to the hour starting at 6am) and evohome decides the water is hot enough just before 7am, which is when the first zone demands heat. More zones demand heat at 8 and 8:30 (one can see the return temperature dip as more radiator valves open), and from a little after 9am, the zones are all close to temperature and evohome drops into TPI operation, which continues over most of the day.

There was an octopus saving session for an hour starting at 5:30pm and, in the interests of minimising electricity consumption by the boiler and pump, I turned the heating off then too.

Mine is an S-plan system and until recently I had been unclear how to ensure that the boiler was always condensing fully: the high flow temperature apparently required for water heating seemed to be a problem and for a while I didn’t use the boiler to reheat the HW cylinder at all (using the immersion heater instead). This meant I could set the boiler flow temperature very low (e.g. 37 degC was fine in the mild autumn we’ve had) and be sure that it was condensing fully. The heat-only boiler being used in the way its name would imply, perhaps.

Independent of this, I’d limited the maximum output of the boiler to 25% (because 8 kW was my estimate of what’s needed to to meet the highest demand for heating I’d seen in recent winters) and set the pump speed to low. Both of these changes helped quieten what had been a troublingly noisy set up.

It happens that this combination of heating power and flow speed leads to a delta T at the boiler of around 9 degC. That does the trick, re condensing, because my measurements showed that the return temperature is mostly around 30 degC (see the plot above), only rising towards 40 degC in the recent cold weather. This ensures that even the boiler flow temperature remains far below the point (a maximum return temp of 55 degC) where condensation is said to happen. Sure enough, the clouds of “steam” commonly seen coming out of boiler flues are completely absent in my case. I infer that all the steam is actually condensing in the heat exchanger, usefully, instead of when the exhaust gases emerge from the flue into the cool outside air.

Belatedly, I realised that I could set the maximum boiler flow temperature to 60 degC and be confident that evohome would cut its demand for heat and turn the boiler off long before the actual flow temperature gets anywhere near the set value. This is confirmed by the plot (in particular the many hours in TPI mode, when evohome is calling for heat for a minute or two at a time, once every 10 minutes. What I called crude but effective.

With this setup, and relying on the “hot water priority” setting in evohome, it is safe to let the boiler reheat the water in the cylinder. (I had the installer connect both the coils, so the cylinder has a very efficient heat exchanger, and the measured return temperature ramps up over the course of an hour or so starting at 6am. The boiler flow temperature does eventually get to the set value, 60 degC, at which point it gradually modulates its output down from 25% to the minimum (claimed by Viessmann to be 10%, i.e. 3.2 kW). At around this time, evohome turns the boiler off because the stored hot water has exceeded its set temperature, 51 degC.

At this point the hot water priority no longer applies and the piping hot water in the system is diverted straight into the radiators, just when evohome starts to warm up the first zone.

The measured return temperature then plummets from around 56 deg C to around 25 degC as soon as any radiator valves open and, immediately, the boiler is back and condensing completely.

Sorry for the long and wordy post, but with this measurement, I have little doubt that the boiler is working properly, and I’ll guess that heat is being extracted from the burning gas with a %age efficiency which is in the high 90s (apart possibly from a few minutes towards the end of the water heating). I’m left thinking about boiler condensing efficiency in a way that has strong parallels with heat pump CoP: they both need a low return temperature.

PS - to answer some questions, the internet weather info isn’t really the whole story for us - ours is a leaky house and the killer is when lowish temperatures combine with a stiff ESE breeze. A low outside temperature with no wind isn’t such a problem. But I’m trying the “internet-based weather compensation” anyway. Too soon to tell.

PPS - as a “heat-only” boiler with an external pump, the scope for being clever is pretty limited: only one output temperature (the maximum flow temperature can be set in degC), and a maximum output power can be set (between 100% i.e. 32 kW and 11% which is not quite the 10% advertised, but is near enough that I don’t care). From observation, the boiler fires up at over 25% output and has a period of grace (which may be as long as a minute) during which the burn has to stabilise and during this time it will modulate down to its maximum setting, or below if needed to avoid exceeding the set flow temperature. I dare say that “system” and “combi” boilers can do more, as they can manipulate the speed of the flow from the internal pump.