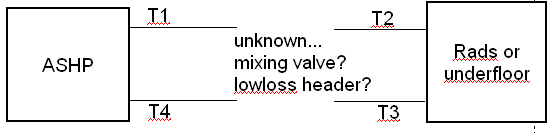

I look forward to seeing your graphs too… As Trystan says, a lot can be gleaned from just temperatures and input power. I’m not sure you have covered this, but its nice to verify that the flow from heat pump and also the flow at manifold of radiators are approximately the same temperature, .likewise that heating circuit return is about the same as the return at the heat pump.

To be clear…

You need to know that your heat pump doesnt ‘see’ hotter temperatures than your heating system is getting. If T1=T2, and T3=T4, then you can remove and re-purpose T2 & T3

Bit late to the party … but might be useful!

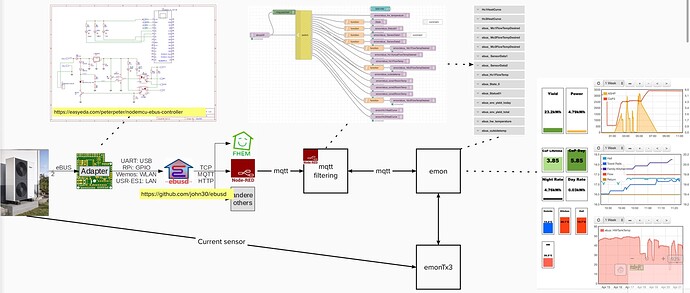

Vaillant heat pump’s internal data (yield, flow temps etc) can be interrogated via ebus.

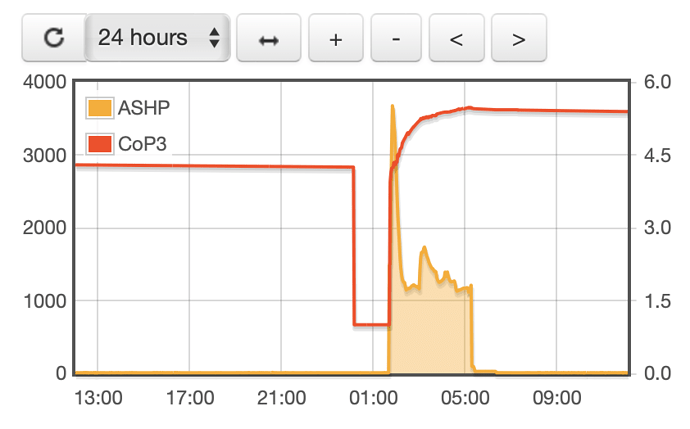

I have hooked up ebusd to emon via MQTT. Using emonTX3 to measure consumption it’s possible to calculate CoP.

I think details of how you did that might be useful to others reading this. Would you be able to describe what you’ve put in place?

Yeah agreed I would very much appreciate some info on how this can be achieved. I understand that an additional control is needed to interrogate the Vaillant directly but found it tricky to get accurate info on a viable process.

This is the place I started: GitHub - john30/ebusd: daemon for communication with eBUS heating systems

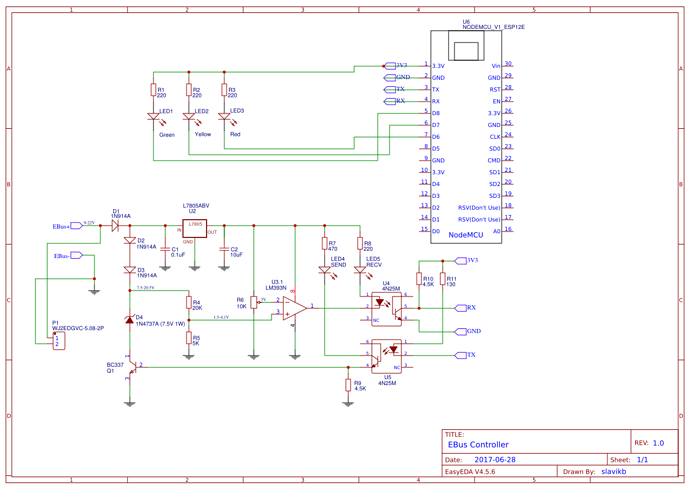

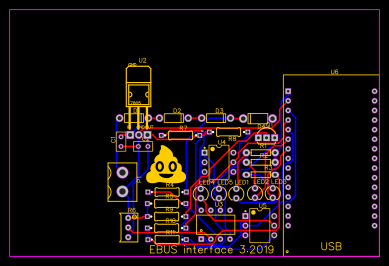

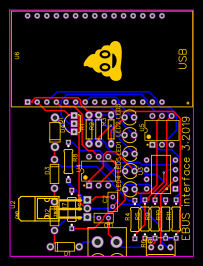

An adapter is needed to read the ebus signals, in the end I built my own using the circuit below. I’m on the waiting list for the commercial adapter since October.

The adapter interfaces with ebusd which runs on a Pi. This then mqtts to node red (same Pi) where conversion and filtering is done from the ebusd topics to the emon topics. There are hundreds of ebus messages, so it was a combination of trial and error to find those relevant for the aerotherm+. ebusd does do a lot of the heavy work. It’s a bit quirky, but very good.

From there on it’s standard emon feeds.

[Just in case that EasyEDA link suffers bit-rot, here are the principal images and BOM (Moderator - RW)]

nodeMCU-ebus-controller_BOM.pdf (24.5 KB)

Did you do a PCB?

@TrystanLea @glyn.hudson might this be something OEM could do? Could be a great addition to the shop.

[edit]

@modeller - the NR Nodes you use to do the decoding would be useful. Either paste as text or attach as a text file.

Are there specific settings on the ebusd?

I built the circuit on a breadboard, which has been running happily for 5 months, whilst I wait for an Adapter 3 to be available.

Adapter 3 is far more sophisticated than the circuit I built and seems to do a lot more in software than hardware - E.g. auto level adjustment.

The circuit I built (it wasn’t my design) is similar to Adapter 2, and requires a Wemos MCU to get the messages back to the ebusd service on the Pi. This Wemos D1 is using firmware from the ebus adapter 3 project; interestingly they only publish the binary, no code is available.

ebusd is just run with settings pointing it at the IP address of the Wemos adapter and the MQTT server.

This is very cool, do you know what models of heat pumps are supported? Is it just Vaillant models, or might other manufacturers heatpumps also use eBus? Do you have a list of the metrics available on the eBus?

I know Atag boilers have an ebus interface and the one linked to, just seems to read the ebus. Just had one fitted (replaced a Vaillant Boiler that has turned up its toes after less than 8 years) and have been chatting to their Tech guys. They don’t have an interface device bar their expensive one which I do not need ![]() .

.

@glyn.hudson - if this is something of interest to OEM, there are a few threads on the forum re ebus/ebusd.

Perhaps worth splitting this into a new thread?

I’d be very interested in an ebus interface card.

Yes, however, Trystan and I don’t have any time to work this currently. We’re flat out working on our hardware re-design. But finding ways to monitor heat pumps in a more cost-effective and efficient way is something we’re very interested in. Starting a new topic and documenting current developments would be a great start. I guess since neither Trystan or myself have access to Vaillant or Atag hardware, there’s not much we can contribute to development and testing at present.