Hi, i’ve managed to get a nice number with this calculations:

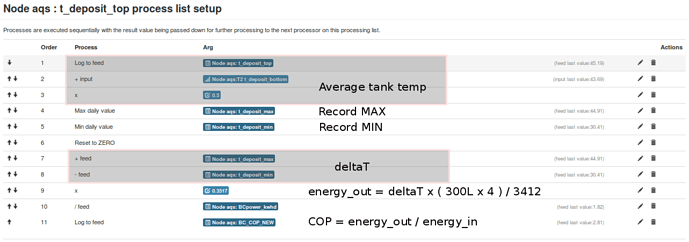

My available sensors are:

- one CT measuring the whole energy consumption of the system

- two DS18B20 temperature sensors, one on the top and another on the bottom of the tank

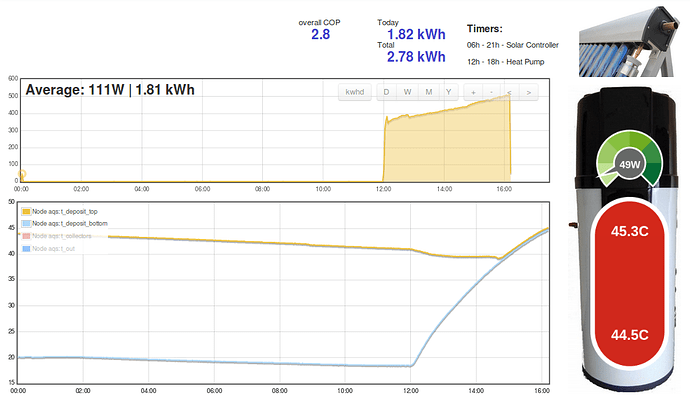

Today with exclusive contribution from the heat pump (no sun), the result is a COP of 2.8.

The datasheet of my heatpump, for this outside temperature (11ºC) and heating cycle ( 15ºC-45ºC) reports a COP value of around 3.

I think that if the calculations are fundamentally correct, the error is not that important, what matters is how the COP behaves as the system gets older.