Hi @datoon,

That’s good to hear things are moving in the right direction and you’re understanding your system.

Going down to about 10-11l/m is consistent with the others on here with the “9” and “11” model designation of the unit you have. And entirely expected.

Flow rate is a big part of the heat output equation.

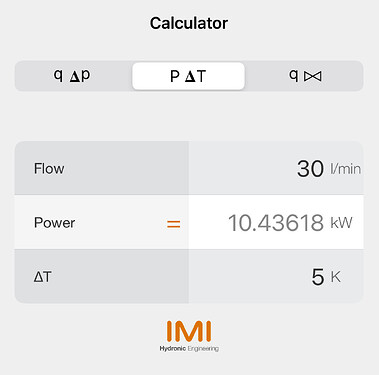

To illustrate that, below shows the heat output (kW) at 30l/m which you said you’ve seen:

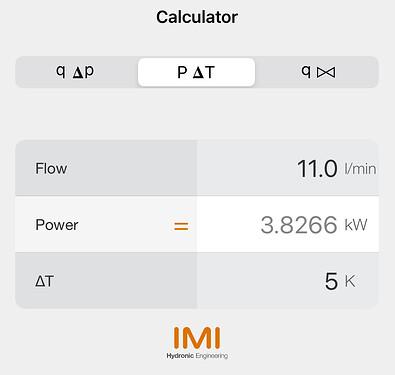

The below shows the flow rate you’re now seeing at “steady state”

You can see that dT between flow and return remains the same, and only flow rate changes.

Unless it’s extremely cold and close to or below design temperature (and even then this is based on your modelled heat loss not actual), you won’t see high flow rates other than initial ramp up or for DWH runs.

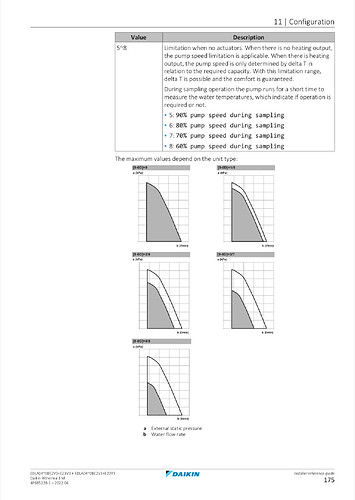

With regards to Pump Limitation: this should be set to “only when sampling” and say 60% when sampling:

You do not want to limit pump speed/power all the time, so be careful to select the right parameter and value (“only when sampling”) as this is useful to minimise electricity usage of the pump in between the compressor being on (eg when in LWT mode and the unit is cycling)

My system and others (I believe) use the Pump limitation - 60% pump speed during sampling value