I’ll chime in as a 14kW Ecodan R410A owner.

Ours cannot modulate down far enough to match our heat demand. The minimum I’ve seen is about 1.8kW input and about 6kW output. It refuses to sit at that low level for very long though. It’s usually bottoming out at 2kW producing 7kW.

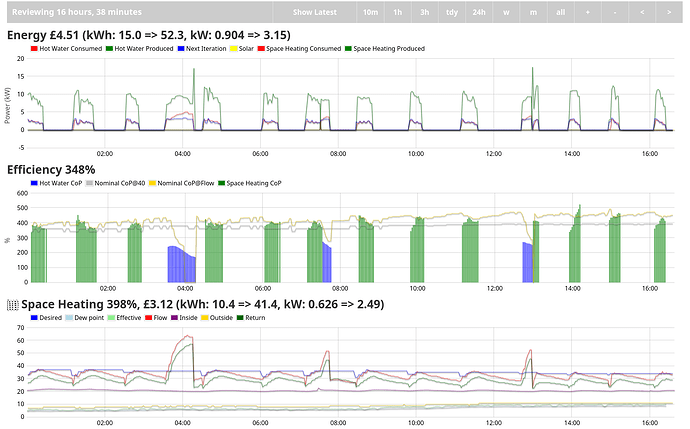

However, that’s not a problem for us because we turn it on and off. For example, today the pumps have been:

Main: 36.3%

Space Heating: 28.9%

Hot Water: 7.4%

So we’ve actually used 900W on average and produced just over 3kW.

I could elect to have some off periods rather than have it running on/off for 24hrs/day

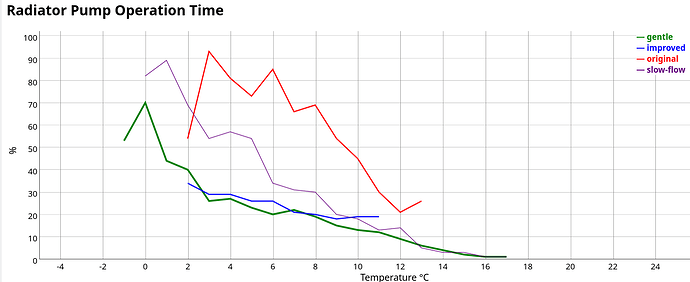

This chart is the amount of time we run the radiators compared to the average daily temperature - focus on the green line:

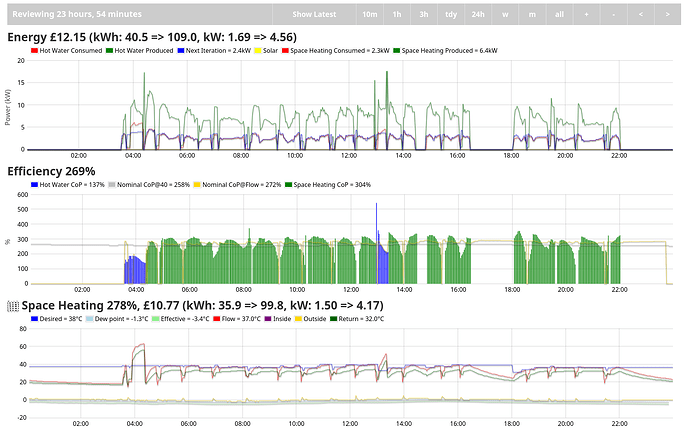

So you can see we practically never run it 24hrs/day. Even on 2023-12-01:

You can see it turned off around 15:00 because it was too warm. (there was also a saving session which is the big gap in the day).

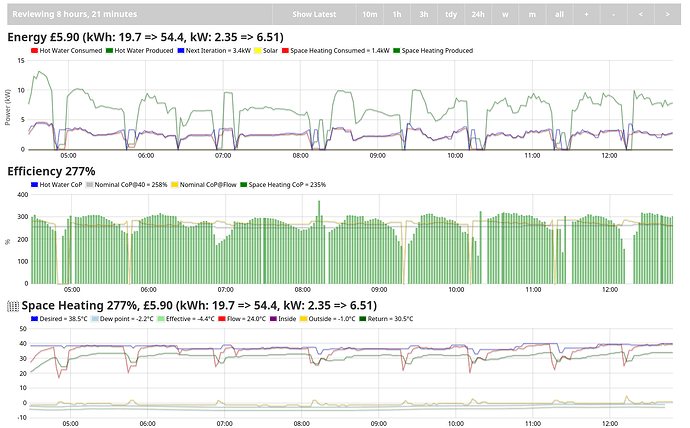

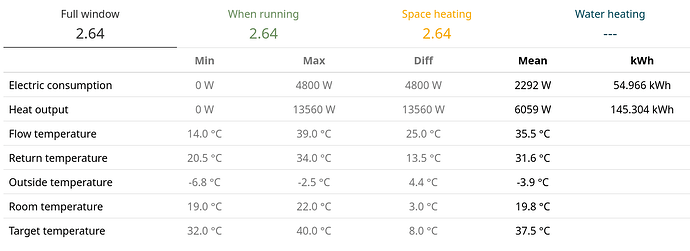

If I zoom into the part where it ran continuously we can see it was still only averaging 6.5kW output:

so it would need to be a lot colder to see it trying to produce 14kW. However, I’m also sure it won’t actually produce 14kW when it’s cold due to defrosts and reduced CoP. Note that our flow temp at -3 °C effective outdoor temp was still only 39 °C so I’ve always considered the design flow temp of 45 °C to be somewhat pessimistic.

Our heat demand calc was 14kW based on previous oil usage.

I continue to be fine with my over-sized pump and having it cycle. Admittedly I wasn’t happy with it cycling every few minutes so you can see we have it doing something like 12 minutes on / 45 minutes off on a day like today.

As you can see here, the room temp continues to rise a bit even when the heat pump is off because the radiators are still warm. Admittedly I do turn the pumps off so I’m not sending that warmth back outside again.

Note that mine is a PUHZ-HW140VHA2 which uses R410A not R32 so you’ll see different behaviour from yours.

It’s nice to see everyone helping you with some good advice on this thread.