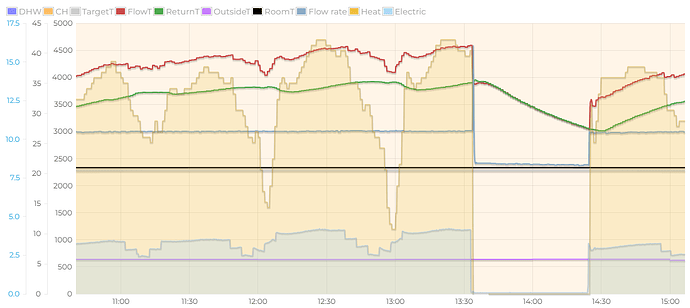

I’m not familiar with that monitor. Do the ‘rev-ups’ make sense? Its this in response to a drop in flow temperature due to a zone coming on?

It doesnt make sense to me. the zone is on all day.

@gekkekoe Do you think I should increase my flow temp?

depends, first confirm that its cycling. You can plot feed and return temp, if the compressor drops to 0hz, and if at that point return temp > feed temp, then its cycling. But it sure looks like it.

Say its cycling, determine (@F1p solution should have calculated this for you) your output just before a dip output with:

output power = flow (L/m) / 60 * (feed - return temp) * 4.2

Compare your output against the databook and see what min output your heatpump has for current ambient temp. Since you did not specify the exact unit, we cannot lookup the min output.

But your output is probably very close to the min output during the dips.

Given the formula above, there are 2 parameters you can tweak

flow: increase pump speed → increase output (with other parameters unchanged)

feed temp: increase feed temp → increase output (with other parameters unchanged)

You can/need also to increase the consuming side (open more heating circuits if possible)

So what do the flow&return temperaures look like?

One thing i learnt a few months back is that the Ecodan algorythms reasses the minimum speed, and even it its trying to reduce the flow temperature, it will ‘reasses’ the minimum speed if the compressor discharge temperature indicates liquid in the suction pipe, it revs-up. Anyhow, not sure what can be done about that. Your cycling looks reasonable. any idea what the average kW output might be?

Thanks for using my solution ![]()

You can get the output power under “Computed Output Power”

In addition, the Flow/Return temperature graph + Flow Setpoint would be helpful ![]()

Are these defrosts or “Off” periods? If it’s defrost then this is normal (ish)

If you have FTC6 firmware 18.00 or around this, the unit does defrost more than required

Hello all!

Red is defrost yellow is off.

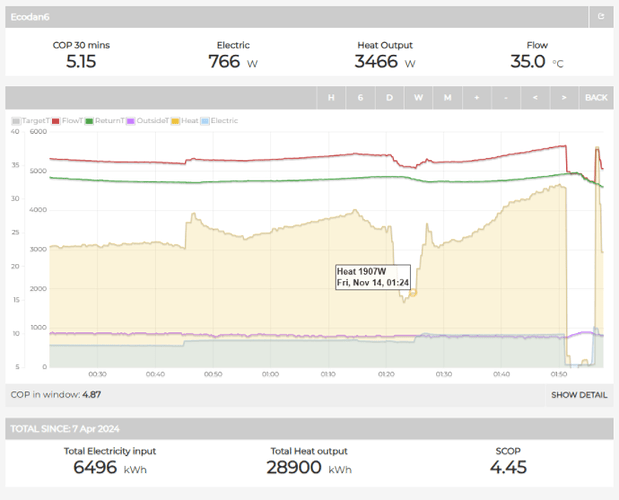

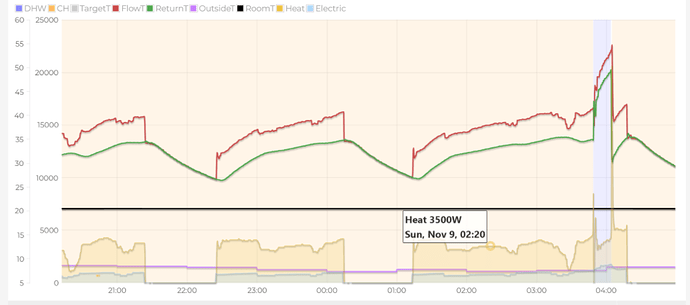

Here is the graphs you requested. Approximately 1.5kW around the cycling time.

Cheers!

My FTC6 Version is: 18.01. Can I update or move that in any way?

Thanks!

Haha it’s bad I can spot a 18.01 just by a graph now…!!

Yes it’s possible to update, will DM you

I think by looking it could be a mixture of both, auto adapt can be better at sorting this out if you have the controller placed in a good location - or consider a wireless thermostat

The controller is sadly at the warmest part of the house…

Could I possibly put it at a high temp lets say 24 and not worry about it?..

6kW Ecodan 19mar2025.pdf (475.0 KB)

A severe ‘crash’ of my 6kW ecodan this morning. No idea why, but I’m sure there was liquid refrigerant flooding back to the compressor. discharge superheat worryingly low

Where/How are you getting the discharge temp?

Its a TO92 (uncased) ds18b20 connected to an EmonTx. I think a normal sensor would do, but since the pipe is about 9mm, it needs a small sensor. I wrapped copper wire around to help. A soldered on 10mm pocket might be better

Ah okay, so not using the mitsi onboard sensor

Thank you for the reply!

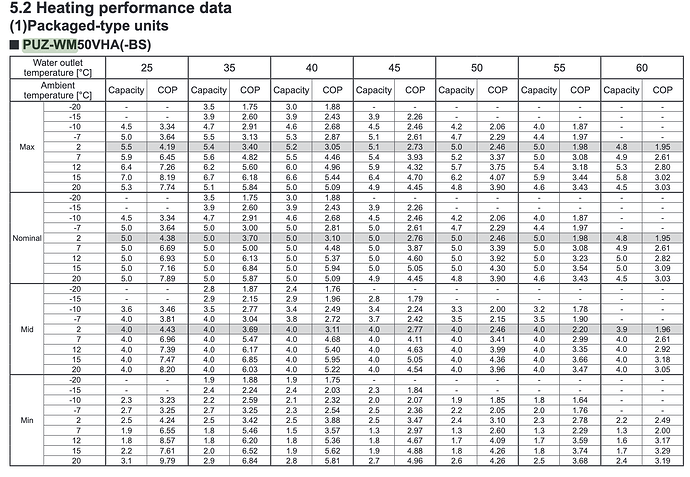

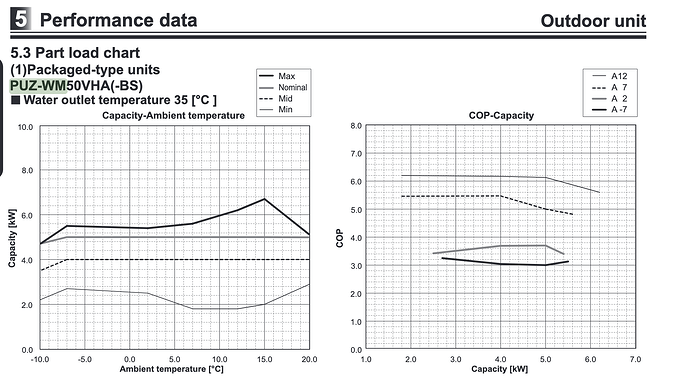

I had a quick look on this and I found the following from the databook for my exact unit:

From this I suppose that I want to stay above 2kW output correct?

lets say I have moved my feed temp as high as I would be willing to go, would increasing the flow (and therefor reducing my deltaT) impact the COP in a negative way?

increasing flow will increase output. Normally when you increase the flow you can reduce the feed temp (thus increasing your COP).

For min output, it depends on the ambient temperature. At 2c you want to stay > 2.5kW but at 7c you can stay above 1.9 kW

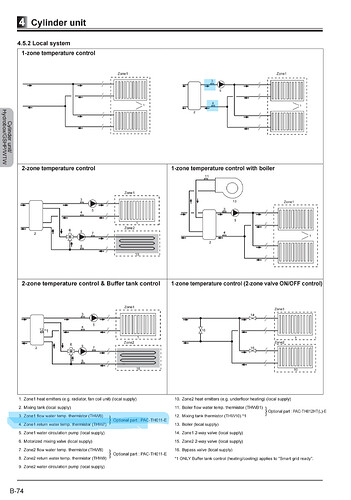

Anyone here getting readings out of THW6/THW7? I connected the mitsu original thermistors, but shows no value for them in the thermistor readings menu.

This is a FTC6 powered unit (PUD-SWM80YAA + cylinder unit EHST20D-YM9D), configured in single zone mode with buffer tank.

According to the little information available in the manual, this looks like it should be possible

I was able to get the values to show if i enable SW2-6 (with mixer tank), but since I don’t have a thermistor for the buffer tank, it alters the unit’s behaviour in a way that it seems to stay always on at close to max output. (probably because it sees those default 25c for THW10)

Dip SW2-6 to on was the solution. The max output behaviour went away after a couple of days. I guess that AA forgets what it learned when the power is cut.

One behaviour change that i noted is that when SW2-6 is set to off, when the unit is not running (primary pump off), the AA setpoint temp follows the primary LWT (THW1), and when SW2-6 is set to on, the setpoint temp follows the secondary LWT (THW6).

This makes sense when you think about it, but just goes to show that there is quite a bit of logic in the FTC

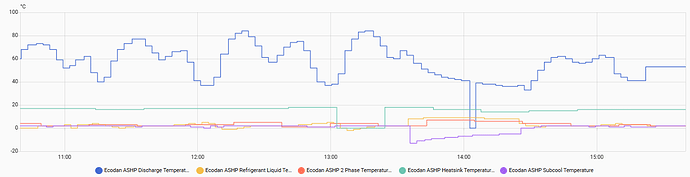

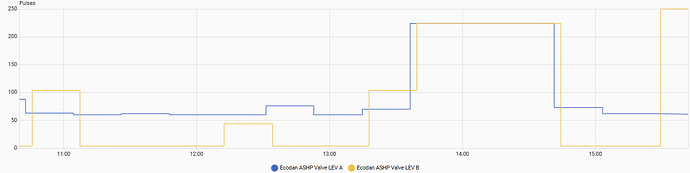

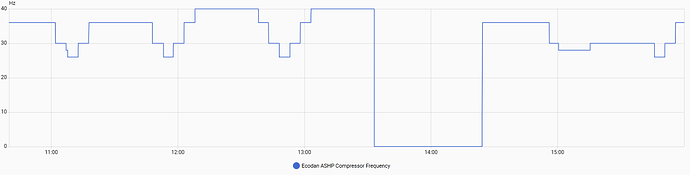

My Ecodan is still fluctuating strangely like before but now with more data thanks to ESP32 connected to CN105.

Everything looks very stable apart from the discharge temperature that seems to drop after the input to the compressor has been reduced before the control algorithm appears to freak out and up the compressor again.

Gosh, that looks really bad. My 6kW shows similar at times, and i was about to gather some info and knock on Mitsi’s door again. Well done for the extra data. I have yet to understand what the LEVs are doing on mine, but they dont seem to worry (respond) when discharge drops, and discharge temperature is main feedback for LEV. If you were to also see compressor frequency, you would see it speed up when discharge drops. Its partly a ‘get out of trouble’ responce. Surely this problem is happening to many 6 and 8.5 kW units. It needs sorting! Such a low discharge temperature must involve a ‘wet’ suction line, and this might affect compressor lubrication… its not good

Yes, interesting. I’m guessing that the target flow temperature is nowhere near the 40c it reached? One would expect it to drop below 25Hz, but it revs up in response to the low discharge temp.. Well… that is what mine does.

A stand-back look at your graphs shows it revving up, then stopping. I never see it stop from minimum as other units do. Mine shows a lot of revups, then stops., then re-starts.

I was looking for steady state on yours. Yours is possibly better than my 6kW. I see it almost achieves steady 3.5kW. But how come it does that here with a steadily rising flow,return temps? is it overshooting the target flow temp?