After closely watching the unit performing today, it seems that the ASHP will only run for 20 minutes before stopping for a breather, regardless as what the thermostat says. I think. It could be that the thermostat sends a short call for heat, and then the ASHP has a minimum running time after that point. I can’t quite tell. The main unit shows it’s “Idle” shortly after starting a cycle. I need to investigate further.

{I came across this forum post on another site that talks about my specific thermostat with a heat pump}

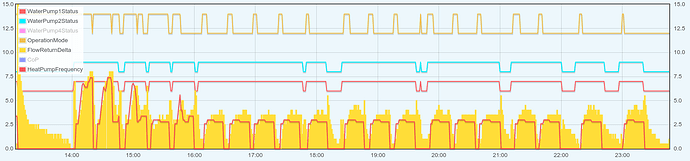

Yes, I think I turned down the room thermostat at this point, so it didn’t call for any heat for a little while. Both the main and central heating pumps turned off at this time. Below is a chart for the same period [Feb 7th]:

- OperationMode goes high at the start of each cycle, but only for short periods for most of the day

I’d be interested to see how this parameter varies on other units - WaterPump1Status (main) and WaterPump2Status (heating) drop to zero between cycles when there’s no call for heat - maybe the thermostat cycles get out of sync with heat pump cycles?

- FlowReturnDelta is dt - mean is 3, most often at 3.5, stdev is 1.5

- HeatPumpFrequency (not to scale) is at 75% at the early part, settling down to 30%

The end of each heat pump cycle is almost always 20 minutes after the OperationMode goes high.

If I look back through at previous days, I can find odd occasions when the OperationMode stayed high for a significant period, and the heat pump ran for longer [Jan 31 around 18:00, it ran for over an hour without stopping], but this is rare.

That’s a good question. I’d have expected that longer cycles less often would be better, to save wear on the compressor at least. Maybe I’m seeing EcoDan’s ‘automatic adaption’ at work, deciding that short cycles are better? The performance I’m getting out of it seems reasonable, though I wouldn’t say no to even high CoP!

This seems a good time to point to @MyForest’s thread about turning off the heatpump to improve efficiency - his first chart shows many short cycles (6 per hour!) that he tamed into longer cycles that were less frequent.

The sensors are very close to the indoor unit, with the external unit quite a distance away (about 10m). I do plot dt (see above), and it’s kinda interesting but I don’t know what it tells me. I do know that I very rarely see a dt above 4°, even after the installer reduced the pump speed. (They told me the system is designed to run between 1-3°)

No underfloor; all newly upgrade radiators (mostly K2).