You’ve got the right idea Matthew.

Your room stat is behaving like ours did - it only seems to do on/off.

I tried getting long runs with my system as documented here:

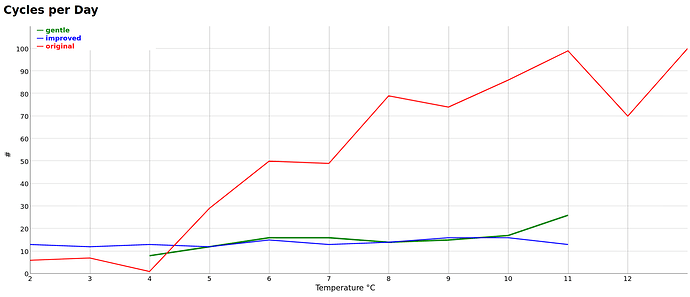

I never managed to get the heat pump to modulate down enough (as you mentioned) so after a while it started cycling again. I reverted to my “switch the heat pump off” strategy. It’ll be interesting to see how your buffer tank might cause yours to behave differently. I was anticipating that the buffer tank would give fewer but longer cycles as it heated up the buffer and then went back to sleep. As you say, if the ASHP flow temp is low then it’ll need to keep nudging the buffer. That wouldn’t work here because the heat pump is in the garden and it’s annoying when we’re outside and it’s on.

Given your setup I might be tempted to just use timed control and let the TRVs manage the temps. We have our bathroom TRVs wide open so they behave like yours. I would expect the ASHP will see your return is getting too hot and shut itself down when it can’t modulate down far enough so you wouldn’t need the room stat to perform that “switch off when warm enough” functionality.

The 100W from the circulating pump sounds plausible, even our pond pump is 65W. Part of the benefit of the “turn it off” strategy is that we don’t have the noise or power consumption of the circulating pump all the time - it only comes on when it’s got something to do.

I’m surprised you need the CH during the day in the UK at the moment, it’s getting to 15 Celsius and we’re having the doors open some of the time (which is inevitable when you have orphaned ducklings living in the house overnight). Moving to a timer would cut out much of your day usage. I can also see that it’s cold overnight (we had a frost a couple of days ago) but we’re finding a single 15 minute run in the morning takes the chill off and we haven’t even done that since Thursday. Perhaps you could avoid all that overnight cycling using the timer too? We’re finding the trick is to shut the doors / windows in time to conserve the heat from the day.

Don’t feel too bad about your cycling…

Good luck.

David