I’ve recently installed a Samsung ASHP (AE050RXYDEG-EU) at my house. Even though I’ve installed full Level 3 heat pump monitoring with a heat meter I’ve also been experimenting with communicating directly with the unit itself.

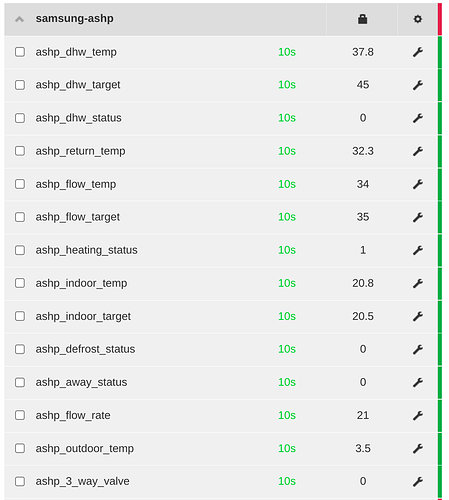

Using the Samsung Modbus Module and a Modbus to USB adaptor I’ve been able to extract the following data:

I started with a simple python script to read the modbus registers which are documented in the modbus module documentation. It’s possible to send control commands, see my test script for details:

Thanks to Homely Energy for helping me get started with this. HomelyEnergy make a smart controller which is compatible with Samsung heatpumps via the same modbus module, they’ve made an excellent video on how to install the modbus module in the outdoor unit.

I don’t have any personal experience with the Homely controller, but it sounds very impressive and has the potential to significantly improve performance of the heatpump, I may try it out myself in the future.

I’ve now added support into EmonHub (V2.3.4 currently in master branch) to read the data and post to Emoncms:

https://guide.openenergymonitor.org/integrations/emonhub-interfacers/#samsung-ashp

Example emonhub config:

[[SAMSUNG-ASHP-MIB19N]]

Type = EmonHubMinimalModbusInterfacer

[[[init_settings]]]

device = /dev/ttyUSB0

baud = 9600

parity = even

datatype = int

[[[runtimesettings]]]

pubchannels = ToEmonCMS,

read_interval = 20

nodename = samsung-ashp

# prefix = sdm_

[[[[meters]]]]

[[[[[ashp]]]]]

device_type = samsung

address = 1

registers = 75,74,72,65,66,68,52,59,58,2,79,87,5,89

names = dhw_temp,dhw_target,dhw_status,return_temp,flow_temp,flow_target,heating_status,indoor_temp,indoor_target, defrost_status,away_status,flow_rate,outdoor_temp,3_way_valve

scales = 0.1,0.1,1,0.1,0.1,0.1,1,0.1,0.1,1,1,0.1,0.1,1

precision = 2,2,1,2,2,2,1,2,2,1,1,2,2,1

It’s nice to have access to this data directly, but unfortunately data like power consumption and flow rate are not available via modbus. Therefore, it’s not possible to calculate COP from this data. However, the Samsung ASHP uses an external Skia flow meter which is usually located indoors, it should be possible to read from the flow meter, then with the addition of CT based power monitoring we will be able to calculate COP without the need for an invasive heat meter. The same (or very similar) Sika flow meters are also used in Mitsubishi EcoDan and Vaillant Arotherm units.

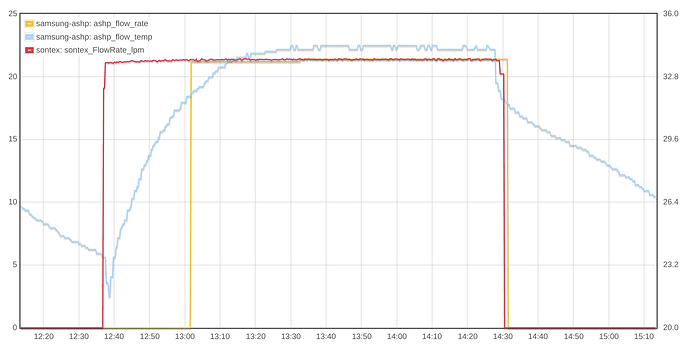

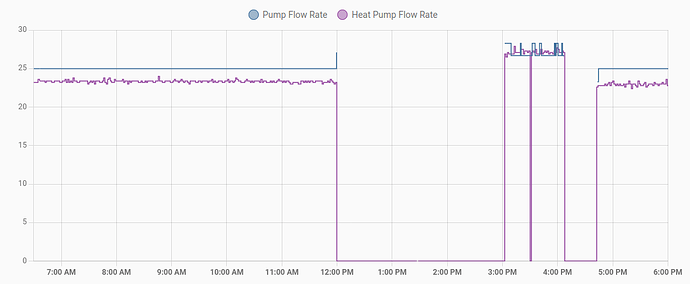

Update: there are some hidden registers which report flow rate, these metrics have been added to emonhub. Unfortunately the flow rate metric updates too slowly to enable COP to be accurately calculated. The flow rate either needs to be read directly from the Skia flow meter or a heat meter e.g Level 3 Heat Pump Monitoring Bundle is still needed to calculate real-time COP.

See this thread for successful efforts to read from the Skia flow meter: