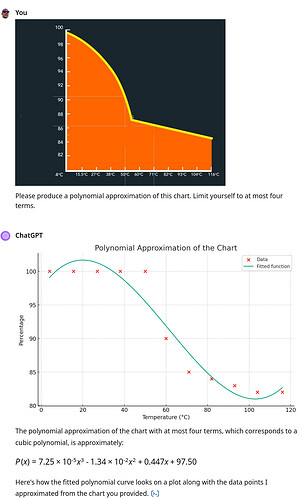

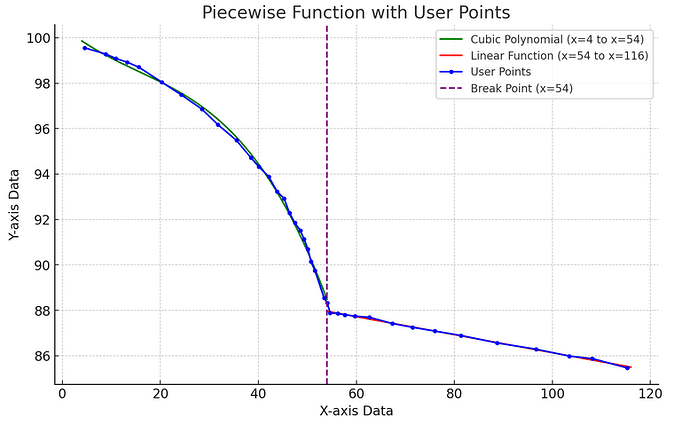

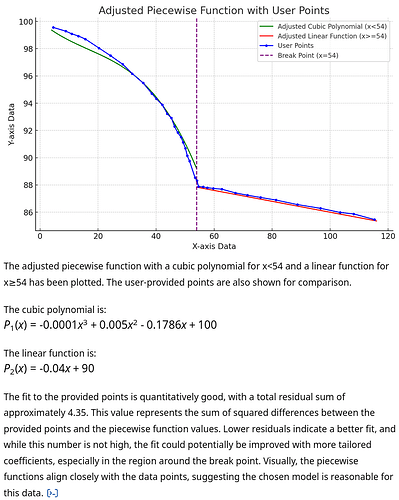

If you want to tinker with the outcome, you can use this in something like Jupyter:

import numpy as np

import matplotlib.pyplot as plt

from scipy.optimize import curve_fit

# Your data points

data_points = np.array([

[4.549, 99.559], [8.863, 99.284], [10.902, 99.091], [13.255, 98.926], [15.608, 98.706],

[20.314, 98.045], [24.235, 97.494], [28.471, 96.861], [31.765, 96.172], [35.529, 95.484],

[38.51, 94.713], [40.078, 94.328], [42.118, 93.887], [43.843, 93.226], [45.255, 92.923],

[46.353, 92.29], [47.451, 91.849], [48.549, 91.519], [49.333, 91.133], [50.118, 90.693],

[50.745, 90.142], [51.529, 89.757], [53.412, 88.545], [54.039, 88.325], [54.667, 87.884],

[56.235, 87.857], [57.647, 87.801], [59.686, 87.746], [62.667, 87.691], [67.373, 87.416],

[71.451, 87.251], [76, 87.086], [81.333, 86.893], [88.706, 86.562], [96.706, 86.287],

[103.451, 85.984], [108.157, 85.874], [115.294, 85.461]

])

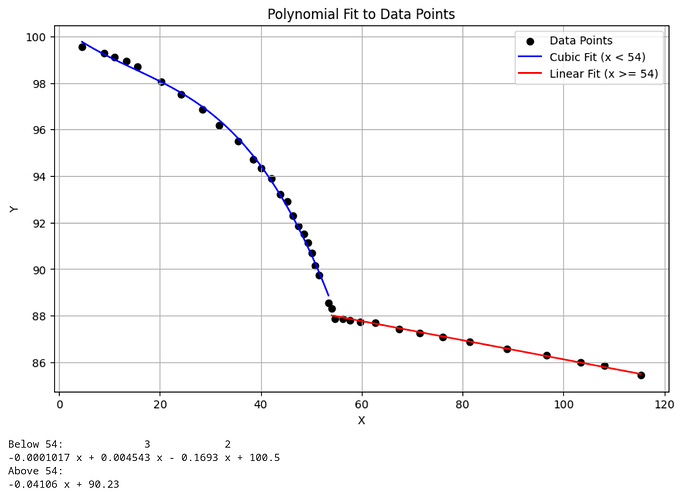

# Split the data at x=54

split_index = np.argwhere(data_points[:, 0] >= 54)[0][0]

data_below_54 = data_points[:split_index]

data_above_54 = data_points[split_index:]

# Fit a cubic polynomial for x < 54

coeffs_below_54 = np.polyfit(data_below_54[:, 0], data_below_54[:, 1], 3)

# Fit a linear polynomial for x >= 54

coeffs_above_54 = np.polyfit(data_above_54[:, 0], data_above_54[:, 1], 1)

# Define the polynomial functions

poly_below_54 = np.poly1d(coeffs_below_54)

poly_above_54 = np.poly1d(coeffs_above_54)

# Create a range of x values for plotting the fit

x_range_below_54 = np.linspace(data_below_54[0, 0], data_below_54[-1, 0], 100)

x_range_above_54 = np.linspace(data_above_54[0, 0], data_above_54[-1, 0], 100)

# Plot the data

plt.figure(figsize=(10, 6))

plt.scatter(data_points[:, 0], data_points[:, 1], color='black', label='Data Points')

plt.plot(x_range_below_54, poly_below_54(x_range_below_54), label='Cubic Fit (x < 54)', color='blue')

plt.plot(x_range_above_54, poly_above_54(x_range_above_54), label='Linear Fit (x >= 54)', color='red')

plt.legend()

plt.xlabel('Return Temperature')

plt.ylabel('Efficiency')

plt.title('Return Water Temperature vs Efficiency for Condensing Boilers')

plt.grid(True)

plt.show()

print("Below 54:",poly_below_54)

print("Above 54:",poly_above_54)