So I’ve bought the 2017 version of the standard from EVS and it’s completely changed ![]() so I may be back to square one with this…

so I may be back to square one with this…

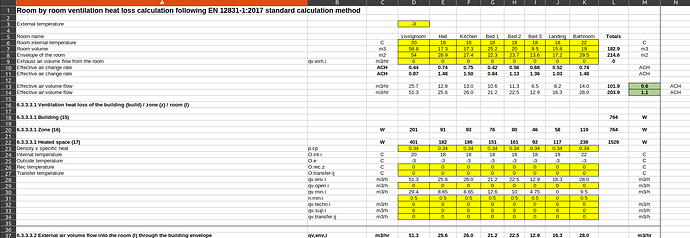

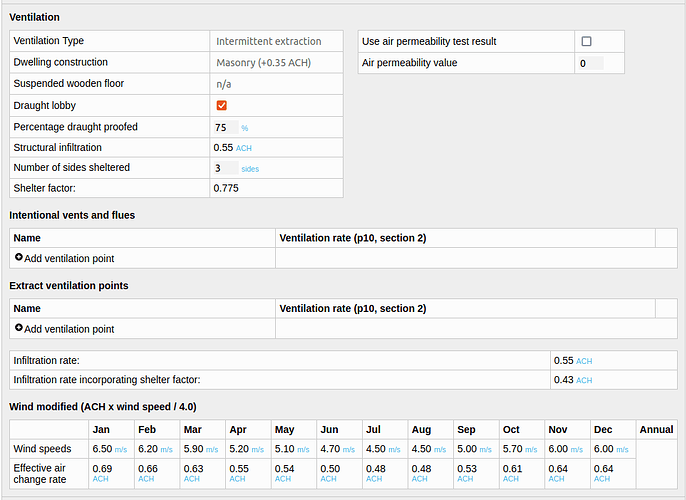

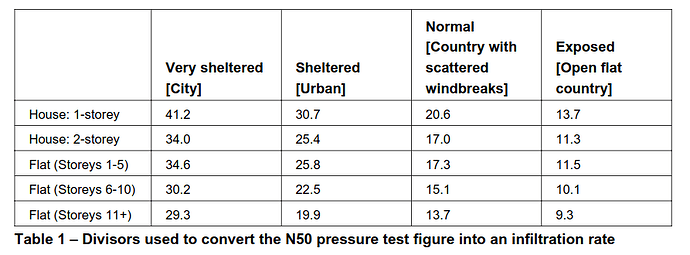

The nice equation for converting an n50 blower door result to a infiltration rate seems to have disappeared, there are no nice worked examples of different ventilation methods only the basic simple one and the equations and descriptions have otherwise got a lot more complicated. They cover a much wider range of internal air movements…

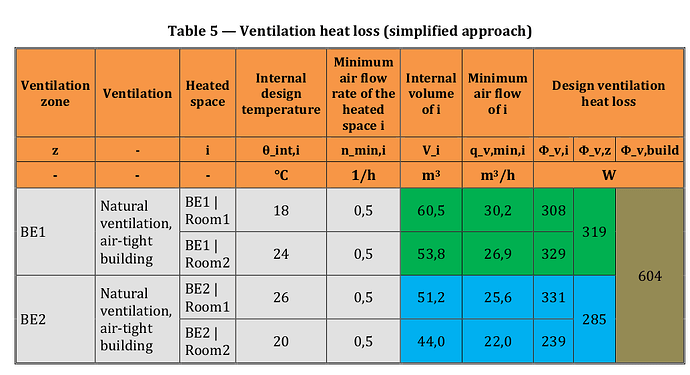

I think for buildings with natural ventilation it just says that you use the simplified calculation method which is the standard method used in heat loss calc.

Correction: After reading through the standard more thoroughly I realised I was wrong in my assessment that it suggests to use the simplified method for natural ventilation, it actually says that the standard calculation method is suitable for all situations and that the simplified method is only suitable for air-tight buildings without forced ventilation. The earlier 2003 standard for the n50 blower test conversion has also just been changed to a different formulation starting with the permeability test result instead.

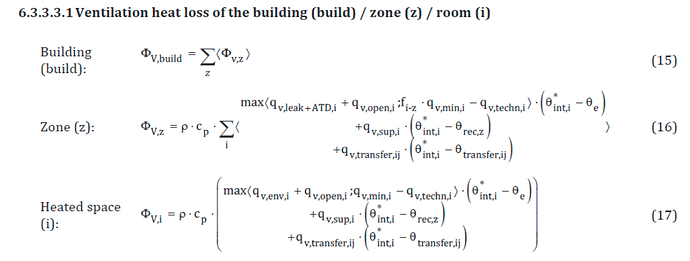

There’s a table B.7 that states that minimum air change rate default values should be 0.5 ACH and secondary / internal rooms 0.0 ACH… but then there’s another table B.12 “Air change rate, default values for simplified methods” which states in the absence of national data:

- Heat loss of single rooms: 0.5 ACH

- n50 < 3: yearof construction >= 1995, buildings with tight windows: 0.25 ACH

- n50 > 3 but <=6: year of construction <1995: 0.5 ACH

- n50 > 6: year of contstruction <1977, buildings with obvious leakages: 1.0 ACH

So not very helpful for my n50 of 10 as that would suggest using 1.0 ACH “in the absence of national data”.

I guess that will teach me to avoid assuming that the standards will not have radically changed between versions!